What's Happening?

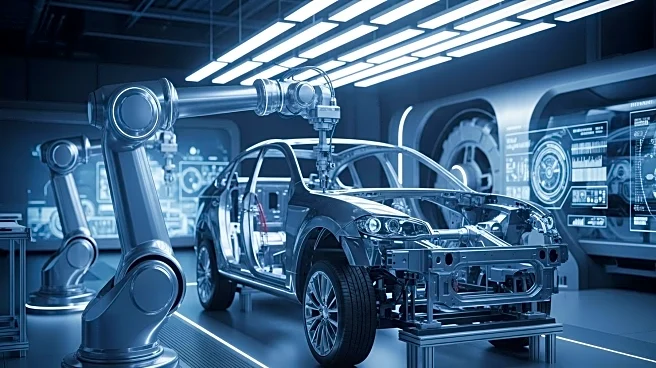

Machina Labs has launched a new manufacturing platform that utilizes AI and robotics to customize automotive body panels and accessories. The platform, known as RoboForming, enables automakers to produce customized vehicles at mass-production prices. The launch was supported by a pilot project with Toyota Motor North America and a strategic investment from Woven Capital, Toyota's venture investment arm. RoboForming technology allows for the production of highly customized panels from sheet metal at high volume and quality, addressing the growing market for automotive customization and accessories. This innovation eliminates the need for dedicated tooling per model variation, reducing project capital and storage requirements.

Why It's Important?

The introduction of AI-driven manufacturing platforms like RoboForming represents a significant advancement in automotive production, offering automakers the ability to deliver customized products at scale. This capability addresses the growing demand for personalized vehicles and accessories, valued at $2.4 billion in 2024 for trucks alone. By reducing the need for dedicated tooling and enabling on-demand part production, Machina Labs' platform enhances efficiency and flexibility in manufacturing processes. This innovation has the potential to transform the automotive industry, providing new value streams and opportunities for customization.

What's Next?

Machina Labs plans to continue developing its AI-driven manufacturing platform, expanding its capabilities to address the needs of the automotive and aerospace industries. The company aims to leverage its technology to support dynamic batching and broadcast-driven manufacturing, allowing for greater flexibility and responsiveness in production processes. As the demand for customized vehicles and accessories grows, Machina Labs is expected to play a key role in driving innovation and efficiency in manufacturing. The company's collaboration with industry partners like Toyota and Woven Capital will likely lead to further advancements and adoption of its technology.

Beyond the Headlines

The shift towards AI-driven manufacturing raises questions about the impact on traditional production methods and workforce dynamics. The elimination of dedicated tooling and the ability to produce customized parts on-demand may lead to changes in factory layouts and processes, requiring adaptation and retraining for workers. Additionally, the focus on customization and personalization may impact consumer expectations and preferences, driving further innovation in product design and manufacturing. Addressing these challenges is essential for ensuring sustainable and responsible growth in the automotive industry.