What's Happening?

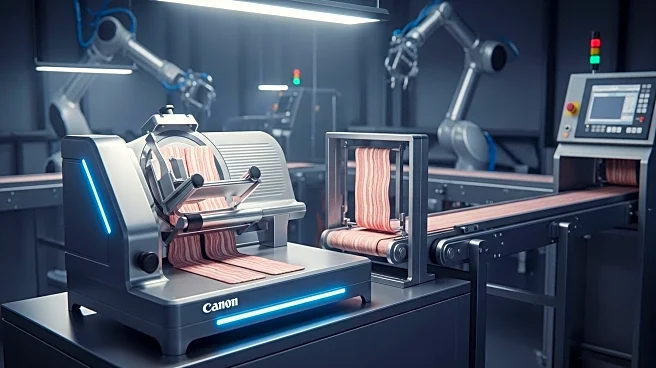

Rockwell Automation has been selected by Middleby Food Processing to develop the food industry's first fully automated bacon production line. This innovation was unveiled at the IFFA trade show in Frankfurt, Germany. Middleby, headquartered in Elgin, Illinois, sought a scalable solution to address rising labor costs, space constraints, and sustainability goals. Rockwell's expertise in engineering and integration was pivotal in creating a unified automation platform that transforms production processes. The solution includes FactoryTalk Optix, which standardizes operator interfaces and application code libraries, enhancing production agility and enabling real-time data strategies.

Why It's Important?

The development of a fully automated bacon production line represents a significant advancement in food manufacturing, offering increased efficiency, reduced labor costs, and improved sustainability. This innovation sets a new standard for automation in the food industry, potentially influencing other manufacturers to adopt similar technologies. By enhancing throughput and reducing wastewater usage, the collaboration between Rockwell and Middleby demonstrates the potential for automation to address key industry challenges and drive future growth.

What's Next?

Middleby Food Processing's automation efforts, powered by Rockwell, extend beyond bacon production to other food segments, including bakery and protein. The adaptability of these solutions allows customers to tailor systems to their unique operational needs, positioning Middleby to stay competitive in a rapidly evolving market. As automation continues to advance, other food manufacturers may explore similar partnerships to enhance their production capabilities and meet sustainability goals.

Beyond the Headlines

The collaboration between Rockwell and Middleby highlights the transformative impact of automation on traditional food manufacturing processes. As the industry faces increasing pressure to improve efficiency and sustainability, the integration of advanced technologies like FactoryTalk Optix could lead to broader adoption of automation across various food segments. This shift may result in long-term changes in production practices, workforce dynamics, and industry standards.