What's Happening?

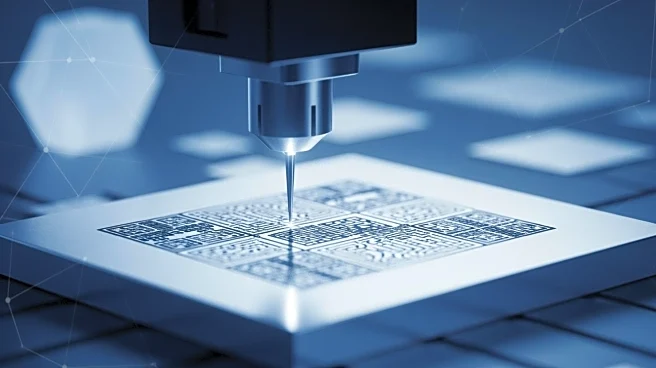

Laser micromachining has become a crucial technique for precise material modification at microscales, offering high-resolution patterning with minimal thermal damage. This technology is widely used in microelectronics,

photonics, biomedical devices, and advanced manufacturing. Recent advancements in ultrafast laser systems, beam shaping, and real-time process monitoring have significantly improved the capabilities and control of laser-material interactions. These developments are pivotal in integrating laser micromachining into emerging technologies, enabling next-generation microfabrication solutions.

Why It's Important?

The advancements in laser micromachining are significant for industries reliant on precision engineering and manufacturing. By minimizing thermal damage and enhancing patterning precision, this technology supports the production of more efficient and reliable microelectronic and photonic devices. This progress is crucial for maintaining competitiveness in the global market, particularly in sectors like semiconductor manufacturing and biomedical device production, where precision and reliability are paramount. The ability to integrate these advancements into existing manufacturing processes can lead to cost reductions and improved product performance.