What's Happening?

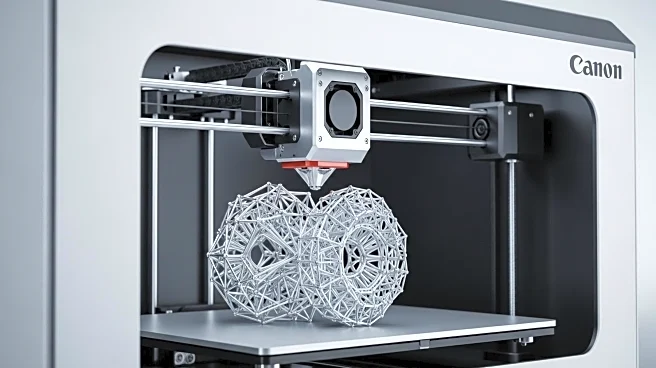

The World Platinum Council (WPIC) has highlighted the evolving role of platinum group metals (PGMs) in 3D printing. Since the development of the first platinum-based powder for 3D printers over a decade ago, PGMs have been increasingly used in additive manufacturing. This technology allows for the creation of complex shapes with high corrosion resistance and strength. The aerospace industry is particularly interested in using PGM powders for manufacturing satellite thrusters and other high-temperature components. The WPIC also notes the potential for 3D printed platinum in the jewelry industry.

Why It's Important?

The use of PGMs in 3D printing represents a significant advancement in manufacturing technology, offering new possibilities for industries requiring high-performance materials. The aerospace sector stands to benefit from the reduced material waste and increased design flexibility that 3D printing with PGMs provides. Additionally, the jewelry industry can explore innovative designs and production methods using 3D printed platinum. This evolution in additive manufacturing could lead to cost savings, increased efficiency, and the development of new products across various sectors.