What's Happening?

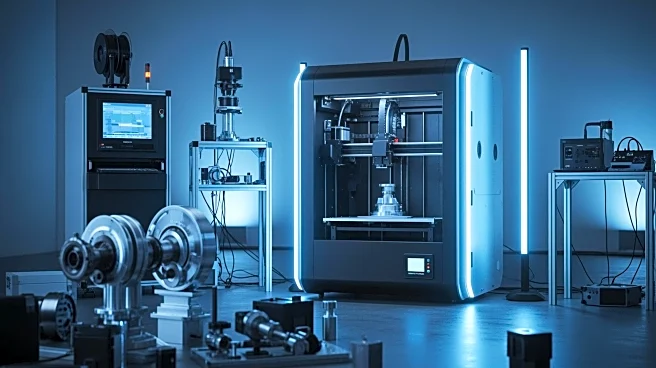

The University of Sheffield has joined the Digitally Enabled Competitive & Sustainable Additive Manufacturing (DECSAM) project, a £38 million UK aerospace programme led by Airbus. The initiative aims to

advance additive manufacturing (AM) technologies, specifically metal laser powder bed fusion (L-PBF), to make them more cost-effective, productive, and sustainable for aerospace applications. The project, funded by Innovate UK, the Aerospace Technology Institute, and the UK Department for Business and Trade, will run until June 2028. It involves 11 organizations, including Airbus Operations Limited, Renishaw plc, and GKN Aerospace Services Limited, among others. The University of Sheffield will leverage its expertise in additive manufacturing and computational modeling to contribute to the project, focusing on resource efficiency, material reuse, and circular design principles to support the aerospace sector's transition toward net-zero manufacturing.

Why It's Important?

The DECSAM programme is significant as it addresses key challenges in the aerospace industry, such as reducing costs, optimizing material use, and improving sustainability. By developing a digitally connected AM supply chain, the project aims to enhance the competitiveness of UK aerospace manufacturing, supporting the industry's move towards net-zero emissions by 2050. The initiative also seeks to mitigate risks associated with single-source casting and advance compact AM-enabled actuation, which could lead to more efficient and cleaner aerospace manufacturing processes. The University of Sheffield's involvement highlights the importance of academic research in driving innovation and supporting industry-focused solutions.

What's Next?

The DECSAM programme will focus on demonstrating the cost competitiveness of AM for aerospace applications through various innovation pillars, including performance, productivity, scalability, and application. Planned outputs include ground and flight-test demonstrators, validated recycled powder routes, and in-process monitoring software offerings. The project aims to accelerate industrial exploitation by providing clear pathways to qualification and certification. As the programme progresses, stakeholders in the aerospace industry will likely monitor its developments closely, considering potential impacts on manufacturing processes and supply chain resilience.

Beyond the Headlines

The DECSAM programme could have broader implications for the aerospace industry by fostering collaboration between academia and industry, driving technological advancements, and promoting sustainable practices. The focus on resource efficiency and material reuse aligns with global efforts to reduce environmental impact and transition to more sustainable manufacturing processes. Additionally, the project's emphasis on digital connectivity and automation may influence future manufacturing strategies, potentially leading to more integrated and efficient production systems.