What's Happening?

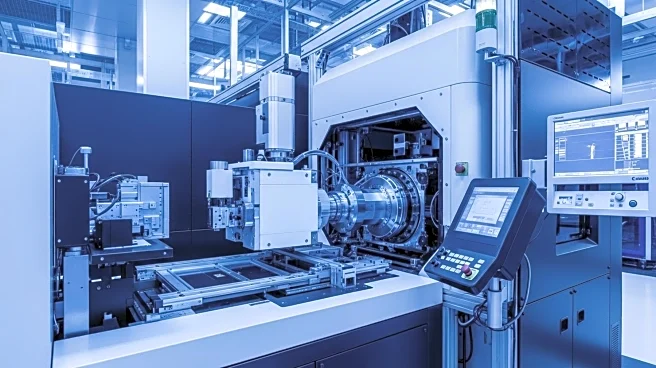

SK Hynix has successfully installed ASML's High-NA EUV lithography system at its M16 fab in Icheon, South Korea, marking the first such tool assembled for mass production. This development is a significant milestone for SK Hynix, as it enables the production of smaller features and higher density DRAM, enhancing its competitive edge over rivals like Samsung and Micron. The High-NA EUV system offers about 40% higher numerical aperture compared to its Low-NA counterpart, allowing for features that are 1.7 times smaller and approximately 2.9 times higher transistor density in a single exposure. The installation of the ASML TWINSCAN EXE:5200B system is expected to accelerate the development and supply of next-generation DRAM, strengthen domestic AI-memory leadership, and improve supply-chain stability through close partner collaboration.

Why It's Important?

The installation of the High-NA EUV lithography tool positions SK Hynix ahead of its competitors in the next-generation memory market. This technological advancement is crucial for the company's strategy to lead in AI-memory and DRAM production, which are essential components in various high-tech applications. The ability to produce smaller and denser memory chips can significantly impact the semiconductor industry, potentially leading to more efficient and powerful electronic devices. As the demand for advanced memory solutions grows, SK Hynix's early adoption of High-NA EUV technology could provide a competitive advantage, influencing market dynamics and driving innovation in the sector.

What's Next?

SK Hynix plans to rapidly prototype new DRAM structures using the High-NA EUV system, including capacitor trenches, bitlines, and wordlines, to accelerate node development. The company aims to simplify existing EUV process flows to improve cost competitiveness as development matures. Future DRAMs are expected to transition to High-NA EUV around the 2030s, and SK Hynix's early adoption of this technology derisks that path. The company will continue to expand its EUV footprint into DRAM production, maintaining its competitive edge in the market.