What's Happening?

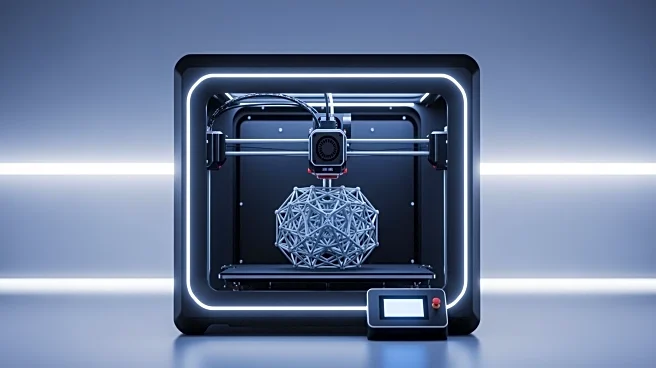

Additive manufacturing (AM) is transitioning from a backup plan to a baseline in modern production environments. This shift is driven by the technology's ability to solve supply chain bottlenecks, reduce lead times, and enable design flexibility. Industries

such as aerospace, automotive, and consumer electronics are increasingly adopting AM for faster iterations and lighter parts, marking a significant evolution in manufacturing processes.

Why It's Important?

The adoption of additive manufacturing represents a transformative change in production methodologies, offering strategic advantages such as reduced tooling costs and increased design freedom. This shift is particularly beneficial in industries with complex supply chains and long equipment lifespans. As AM becomes more integrated into mainstream production, it is expected to drive innovation, efficiency, and competitiveness across various sectors.

What's Next?

As additive manufacturing continues to gain traction, companies will need to develop digital skills and simulation expertise to fully leverage its potential. The technology's integration into existing workflows will require strategic planning and investment in digital capabilities. The ongoing evolution of AM is likely to spur further advancements in materials and hybrid manufacturing approaches, enhancing its applicability and impact.

Beyond the Headlines

The rise of additive manufacturing is not just a technological shift but also a cultural one, requiring a change in mindset towards digital-first processes. This evolution is expected to influence industry standards, regulatory frameworks, and workforce skills, shaping the future of manufacturing. The technology's potential to localize production and reduce environmental impact further underscores its significance in the global manufacturing landscape.