What's Happening?

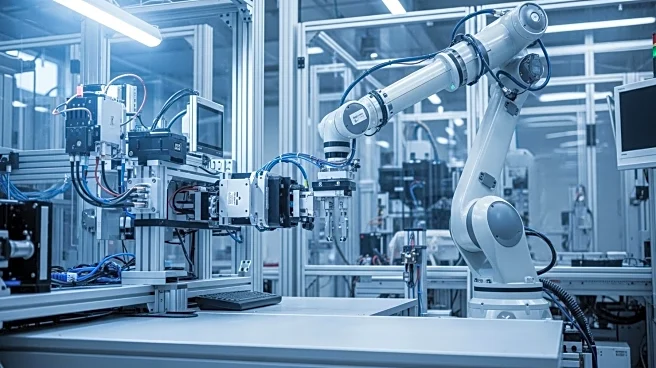

Daifuku has completed a significant expansion of its manufacturing plant in Hobart, Indiana, operated by its US subsidiary, Daifuku Intralogistics America Corporation (ILUS). This expansion doubles the production capacity to meet the increasing demand for automation systems in North America. The facility, which originally opened in 2020, produces conveyors, sorters, and automated storage and retrieval systems for distribution centers and manufacturing plants. The expansion project, which began in April 2024, involved an investment of approximately 5 billion yen ($35 million) and adds 25,000 square meters of manufacturing space to the existing 30,000 square meters. The total site area now spans around 178,000 square meters. This development is aimed at addressing the growing demand for automation driven by labor shortages and higher operating costs.

Why It's Important?

The expansion of Daifuku's US factory is a strategic move to enhance its competitiveness in the North American market, which is experiencing a surge in automation needs due to domestic labor shortages and rising operational costs. By increasing its production capacity, Daifuku is better positioned to provide faster production, streamlined operations, and shorter lead times for its customers. This expansion supports the company's policy of local production for local consumption, which is crucial for meeting the specific needs of US logistics and manufacturing companies. As automation becomes increasingly vital for efficiency and cost management, Daifuku's expanded capabilities could significantly impact the industry by providing essential infrastructure to support these technological advancements.

What's Next?

With the expanded facility, Daifuku plans to further bolster its global intralogistics business, focusing on the US as its largest growth market. The company aims to continue enhancing its competitiveness by addressing the automation needs of US logistics and manufacturing sectors. This expansion may lead to increased employment opportunities and further investments in technology and infrastructure to support the growing demand for automation solutions. Stakeholders, including industry leaders and policymakers, may closely monitor Daifuku's progress as it adapts to the evolving market dynamics and contributes to the broader trend of automation in the US.

Beyond the Headlines

The expansion of Daifuku's factory in Indiana highlights the broader trend of increasing automation in response to labor shortages and rising costs. This development may have ethical and cultural implications, as automation can lead to shifts in employment patterns and require workers to adapt to new technologies. Additionally, the focus on local production for local consumption reflects a growing emphasis on sustainability and efficiency in manufacturing practices. As automation continues to evolve, companies like Daifuku play a crucial role in shaping the future of logistics and manufacturing, potentially influencing industry standards and practices.