What's Happening?

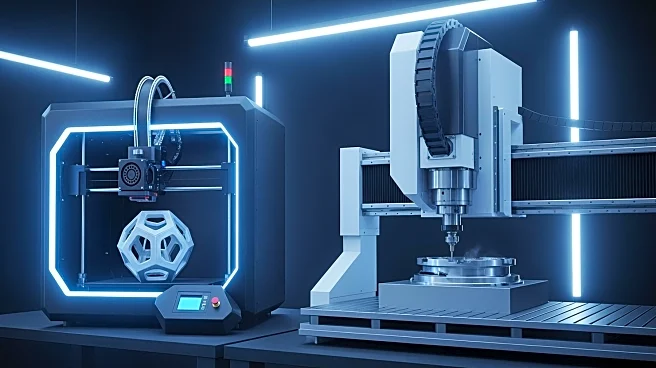

Hybrid manufacturing, combining 3D printing and CNC machining, is transforming production processes by significantly reducing manufacturing times and material waste. This method uses a robotic arm with

a directed energy deposition printhead to create a 'near-net shape' of metal, which is then refined by a CNC toolhead to meet precise specifications. This approach has reduced the production time of critical spare parts from 8-10 weeks to just 72 hours. Additionally, it minimizes material waste, especially when using expensive metals like titanium, by up to 97% compared to traditional machining.

Why It's Important?

The adoption of hybrid manufacturing techniques represents a major advancement in industrial production, offering substantial time and cost savings. By reducing the need for multiple machines and minimizing material waste, companies can achieve greater efficiency and sustainability. This is particularly beneficial in industries that rely on high-value materials, such as aerospace and automotive sectors. The ability to produce parts rapidly also enhances supply chain resilience, allowing for quicker responses to demand fluctuations and reducing downtime.