What's Happening?

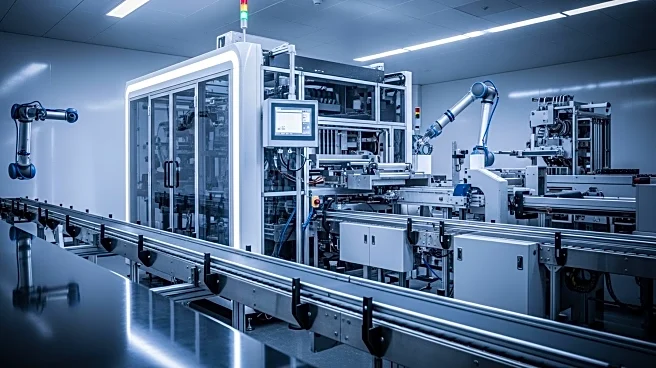

The recent Pack Expo in Las Vegas showcased advancements in food and beverage manufacturing, focusing on sustainability, automation, and efficiency. Key trends included the introduction of new aseptic beverage container sizes by Tetra Pak, freeze-drying

capabilities by GEA, and reusable packaging solutions by Orbis. The event emphasized the importance of adapting to consumer demands for convenience and sustainability, with companies presenting solutions that enhance production processes and reduce environmental impact.

Why It's Important?

The innovations presented at Pack Expo reflect the industry's response to evolving consumer preferences and regulatory pressures for sustainable practices. By adopting advanced technologies and efficient packaging solutions, manufacturers can improve operational efficiency, reduce waste, and meet the growing demand for eco-friendly products. These developments are crucial for maintaining competitiveness in the global market and addressing environmental concerns associated with food production.

What's Next?

Manufacturers are likely to continue investing in technologies that enhance sustainability and efficiency, driven by consumer demand and regulatory requirements. The focus will be on integrating automation and innovative packaging solutions to streamline operations and reduce costs. Industry collaboration and partnerships may also play a role in advancing these initiatives, fostering a collective effort to achieve sustainability goals.

Beyond the Headlines

The emphasis on sustainability and automation at Pack Expo highlights broader industry shifts towards environmentally responsible practices and technological innovation. These trends are expected to influence future product development and manufacturing strategies, promoting a more sustainable and efficient food production system.