What's Happening?

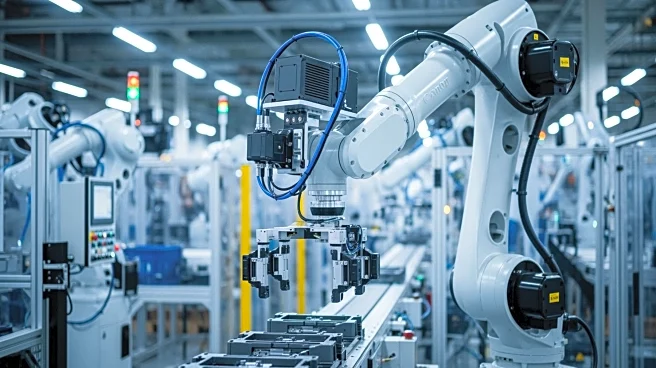

The manufacturing industry is undergoing a transformation with the rise of autonomous data management systems. By 2026, data management in manufacturing will shift from manual processes to AI-driven systems that autonomously organize, analyze, and act on data.

This change is driven by the integration of agentic AI, which allows data to detect anomalies and initiate corrective actions without human intervention. AI agents are being used to clean, validate, and reconcile data, reducing downtime and ensuring accurate decision-making. The adoption of AI-driven digital twins is also enhancing supply chain management by simulating scenarios and recommending proactive actions. This shift is crucial for addressing challenges such as sustainability, regulatory compliance, and operational efficiency.

Why It's Important?

The move towards autonomous data management is essential for the manufacturing industry to remain competitive and efficient. AI systems reduce the latency between data collection and action, enabling faster decision-making and risk management. By automating routine data tasks, manufacturers can focus on innovation and problem-solving, improving overall productivity. The integration of AI also strengthens compliance and accountability, reducing human error and enhancing transparency. As the global AI in manufacturing market grows, companies that adopt these technologies will likely outperform those relying on traditional methods, driving industry-wide change.

What's Next?

Manufacturing leaders are encouraged to invest in strong data foundations to support AI systems. Starting with high-impact pilots, such as predictive maintenance, can demonstrate value and facilitate scaling. Maintaining human oversight is crucial to ensure transparency and regulatory compliance. As AI systems become more integrated, manufacturers will need to focus on ecosystem-wide orchestration to unlock the full potential of autonomous data management. The industry is expected to continue evolving, with AI playing a central role in shaping the future of manufacturing operations.

Beyond the Headlines

The rise of autonomous data management systems could lead to significant shifts in manufacturing practices and workforce dynamics. As AI takes on more data management tasks, human roles may evolve to focus on strategic oversight and innovation. Ethical considerations around data privacy and security will become increasingly important as AI systems handle sensitive information. Long-term, the successful integration of AI could redefine manufacturing excellence, with data becoming a trusted partner in optimizing outcomes.