What's Happening?

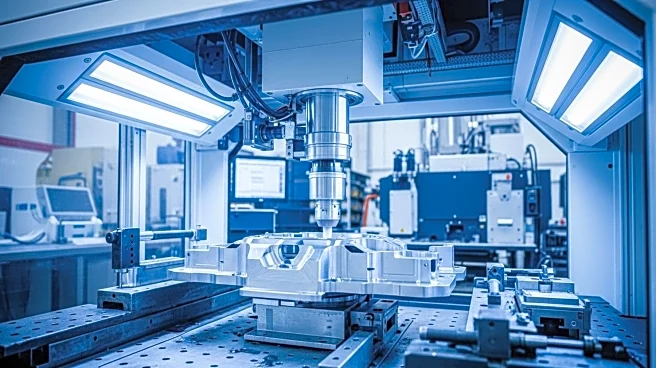

Manufacturers are increasingly focusing on smarter surface processing techniques to improve component performance and reliability. Surface finishing, particularly edge finishing, is a critical yet often overlooked stage in precision manufacturing. It plays a vital role in industries such as aerospace, power generation, and medical devices, where untreated sharp edges can lead to product failure. Traditional methods like manual and robotic brushing are labor-intensive and inconsistent, prompting a shift towards more precise alternatives like Electrochemical Jet Machining (ECJM). ECJM offers cleaner, more precise edge finishing, reducing rework and enhancing supply chain resilience. This method uses a pH-neutral electrolyte, addressing environmental concerns while improving component performance.

Why It's Important?

The adoption of smarter surface processing methods is crucial for manufacturers aiming to meet the rising demands of regulators and customers. By improving component performance and reducing environmental impact, manufacturers can achieve efficiency gains and competitive advantages. The shift towards cleaner technologies like ECJM not only enhances product integrity but also aligns with sustainability goals. This transformation in manufacturing processes is essential for industries that require high precision and reliability, ensuring that manufacturers can maintain their market position and meet future challenges.

What's Next?

Manufacturers are expected to integrate smarter surface processing methods like ECJM into their standard practices. This integration will likely lead to increased adoption of automated solutions that consolidate multiple surface processes, enhancing efficiency and reducing costs. As the importance of surface finishing becomes more recognized, manufacturers will need to adapt quickly to maintain competitive advantages and meet the twin challenges of performance and sustainability.

Beyond the Headlines

The shift towards smarter surface processing has broader implications for the manufacturing industry. It highlights the need for innovation in production processes to address both technical and environmental challenges. This transformation may lead to a reevaluation of manufacturing priorities, emphasizing the importance of sustainability alongside performance. As manufacturers embrace these changes, they will be better equipped to navigate the evolving landscape of precision engineering.