What's Happening?

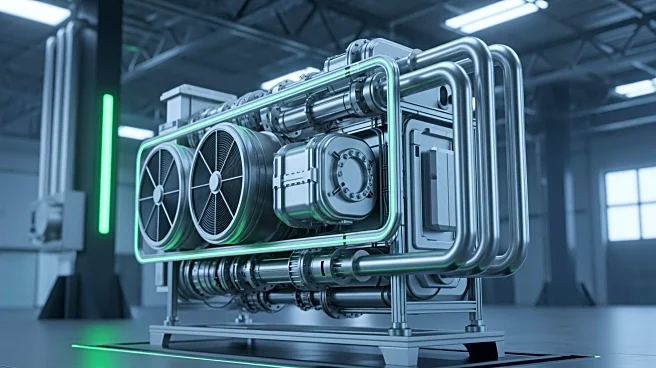

Orcan Energy is advancing waste heat recovery systems in the shipping industry, focusing on Organic Rankine Cycle (ORC) technology. This system captures low-temperature waste heat from ship engines, converting

it into electricity. Orcan Energy has partnered with Goltens to install these systems, which can harness over 100 TWhth of waste heat annually, equivalent to the power consumed by 6.3 million people. The technology is gaining traction for retrofits and new builds, offering a compact solution compared to steam turbines. Recent developments include modular ORC packages for constrained engine rooms and multi-source heat harvesting, enhancing energy efficiency and reducing emissions.

Why It's Important?

The adoption of ORC waste heat recovery systems is crucial for improving energy efficiency in the maritime sector, which traditionally loses over half of its fuel energy as waste heat. By capturing this heat, ships can reduce operational costs and emissions, aligning with global efficiency and emissions regulations. The technology supports the use of alternative fuels, such as methanol, which offer favorable waste heat profiles. This shift not only aids in compliance but also enhances operational flexibility, reducing reliance on slow steaming and promoting sustainable maritime practices.

What's Next?

As the maritime industry continues to explore alternative fuels and energy efficiency measures, the deployment of ORC systems is expected to expand. Orcan Energy and its partners are likely to pursue further installations, leveraging the favorable payback periods and regulatory compliance benefits. The technology's compatibility with new fuels and its ability to operate effectively in various conditions suggest a growing market for waste heat recovery solutions, potentially leading to widespread adoption across the global fleet.

Beyond the Headlines

The integration of ORC systems represents a significant step towards decarbonizing the shipping industry. By reducing emissions and enhancing energy efficiency, these systems contribute to broader environmental goals. The technology also highlights the potential for innovation in traditional industries, encouraging further research and development in energy recovery and sustainable practices.