What's Happening?

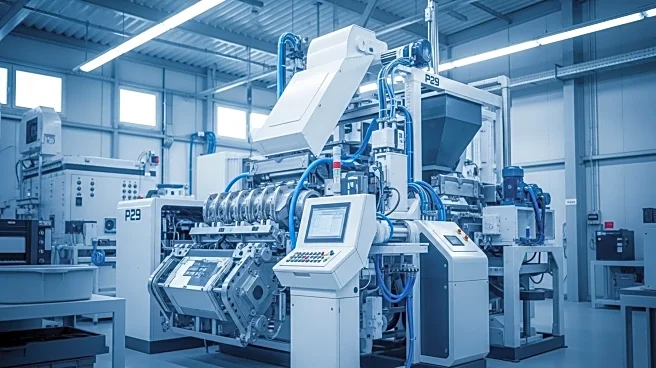

CiDRA Minerals Processing is advancing its P29 system, which is poised to revolutionize mineral processing flowsheets. The P29 system offers a novel approach by increasing grind size and reducing the recirculating load in grinding mills, potentially boosting mill throughput by over 20% at a constant grind size. This technology is gaining traction among major mining companies for its ability to enhance capacity and throughput in existing plants and its potential application in greenfield projects. CiDRA has partnered with Worley and Weir to develop and implement the P29 technology. Worley provides EPC delivery capabilities, while Weir contributes expertise in flowsheet and product development. The collaboration aims to bring the P29 system to market, with a focus on energy savings and improved water recovery in tailings. The technology has shown promising results in pilot plant tests, particularly at BHP's Carrapateena copper operation in South Australia.

Why It's Important?

The P29 system's ability to increase throughput and reduce energy consumption is significant for the mining industry, which faces increasing pressure to improve efficiency and sustainability. By reducing the need for traditional grinding methods and enhancing water recovery, the P29 technology addresses critical challenges such as energy consumption and water scarcity. This is particularly relevant as the demand for minerals grows to support global electrification and net-zero goals. The technology's potential to improve tailings disposal safety and stability further enhances its appeal, offering environmental and operational benefits. As deposits become more remote and challenging to commercialize, innovations like P29 are crucial for maintaining the industry's viability and meeting global mineral demand.

What's Next?

CiDRA plans to advance the P29 technology to a demo scale plant, with discussions underway for its location at an operational site in Australia. The demo plant will be developed by a consortium including CiDRA, Weir, Worley, and other industry partners. The focus will be on accelerating the technology's deployment while managing risks associated with scaling up. The consortium aims to refine the technology for broader industry adoption, addressing questions related to large-scale implementation. The success of the demo plant could pave the way for widespread adoption of the P29 system, offering significant benefits in terms of energy efficiency, water conservation, and operational sustainability.

Beyond the Headlines

The P29 technology represents a shift towards more sustainable mineral processing practices, aligning with broader industry trends towards environmental responsibility. By reducing energy and water usage, the technology supports mining companies' efforts to improve their social license to operate. Additionally, the potential for improved mineral recovery and quality through innovative comminution methods could lead to more efficient resource utilization. As the industry grapples with the challenges of climate change and resource scarcity, technologies like P29 are likely to play a pivotal role in shaping the future of mining.