What is the story about?

What's Happening?

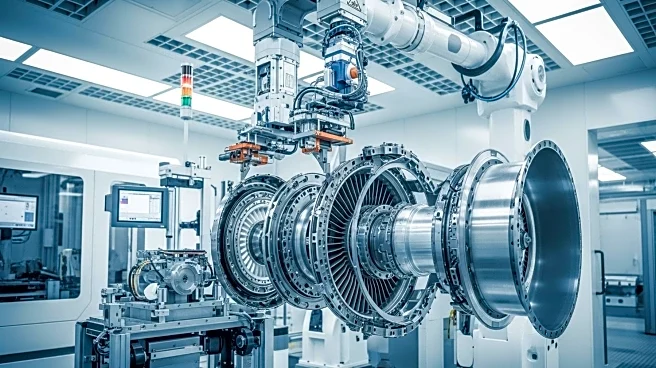

GE Aerospace is ramping up production and repairs of CFM56 engine parts at its Greenville, South Carolina facility to meet increasing demand. The company has significantly increased the production volume of its high-pressure turbine (HPT) blades, which are part of the performance improvement program (PIP) introduced in late 2023. This ramp-up is driven by the strong demand for CFM56-powered narrowbody aircraft, exacerbated by delays in new aircraft deliveries and issues with current-generation engines. GE Aerospace is utilizing its Flight Deck lean operating process and analytics model to balance the output of CFM56-5B and -7B parts with other commitments, such as the CFM Leap production ramp-up.

Why It's Important?

The increased production and repair efforts by GE Aerospace are crucial for maintaining the operational efficiency of airlines relying on CFM56 engines. As new aircraft deliveries face delays, airlines are leaning heavily on existing fleets, necessitating more frequent maintenance and parts replacement. This situation has led to fewer retirements and increased pressure on the supply chain to deliver parts for overhauls. By ramping up production and repairs, GE Aerospace is helping airlines manage costs and maintain serviceability, which is vital for the aviation industry's stability and growth.

What's Next?

GE Aerospace plans to continue investing in repair capabilities to offer cost-saving alternatives to operators. The company is focusing on automating repair processes, such as laser welding for older HPT blades, to increase throughput and reduce turnaround times. These efforts are expected to lower overhaul costs and lessen demand for new materials, thereby supporting the industry's need for used serviceable material (USM). The ongoing dialogue with customers about repair options at every overhaul will be crucial in delivering value and managing the cost of ownership.

Beyond the Headlines

The strategic focus on repairs and production ramp-up by GE Aerospace highlights the broader industry trend of maximizing existing resources amid supply chain challenges. This approach not only supports airlines in managing operational costs but also contributes to sustainability by extending the lifecycle of engine parts. The emphasis on automation and analytics in production processes reflects a shift towards more efficient and technologically advanced manufacturing practices in the aerospace sector.