What's Happening?

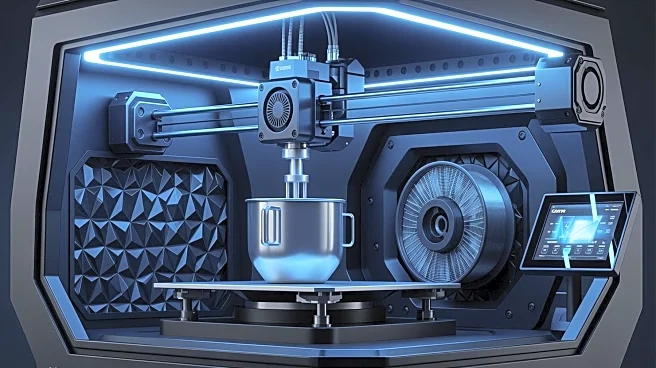

Recent research has focused on the design and performance assessment of custom static intermixers in extrusion 3D printing, utilizing machine learning-driven image analysis. The study evaluates various

mixer designs to enhance the blending of materials, specifically red and blue PLA, in 3D printing processes. The research employs histogram analysis, cluster analysis, and standard index analysis to assess the mixing quality. The findings indicate that advanced mixer designs, such as the Split Path Mixer and Helix Array, significantly improve the uniformity and effectiveness of material blending compared to traditional methods. These mixers demonstrated superior performance in achieving homogeneous color distributions and effective mixing patterns.

Why It's Important?

The advancement in mixer design for 3D printing has significant implications for the manufacturing industry. Improved mixing quality can lead to better material properties, enhancing the durability and functionality of 3D printed products. This development is crucial for industries relying on multi-material fabrication, such as aerospace, automotive, and consumer electronics. By optimizing the blending process, manufacturers can achieve higher precision and quality in their products, potentially reducing costs and material waste. The integration of machine learning in evaluating mixer performance also highlights the growing role of artificial intelligence in industrial applications, paving the way for more efficient and innovative manufacturing solutions.

What's Next?

Future research may focus on further refining mixer designs and exploring their applications in different materials and printing technologies. The continued integration of machine learning and image analysis in 3D printing processes could lead to more automated and adaptive manufacturing systems. Stakeholders in the manufacturing sector may invest in developing and adopting these advanced technologies to maintain competitive advantages. Additionally, collaborations between academia and industry could accelerate the commercialization of these innovations, expanding their impact across various sectors.

Beyond the Headlines

The study also sheds light on the limitations of RGB-based color blending as an indicator of polymer mixing quality. While useful for visual approximation, RGB blending does not provide comprehensive insights into molecular blending or mechanical homogeneity. This highlights the need for more robust measurement techniques, such as rheological testing and thermal imaging, to fully understand and optimize material properties in 3D printing.