What's Happening?

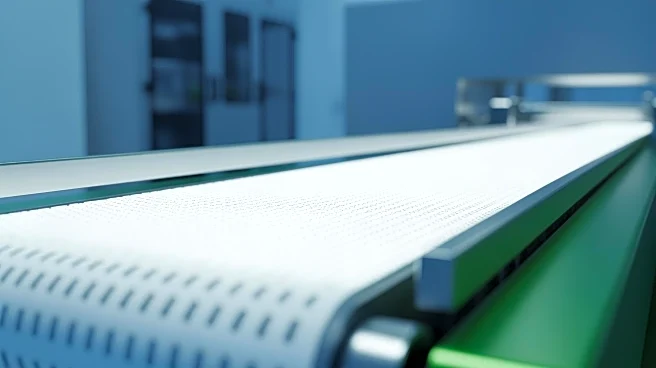

Ammeraal Beltech has unveiled its innovative XMD technology aimed at enhancing food safety by detecting contaminants that traditional metal detectors might miss. This technology integrates X-ray detection with Metal-Detectable features, effectively identifying

foreign bodies across various materials. The introduction of XMD technology is a proactive measure to address contamination risks in the food industry, which can arise from manufacturing and packaging issues, equipment wear, or environmental factors. By catching potential hazards early, XMD technology minimizes contamination risks and safeguards production processes, ultimately saving businesses from the high costs associated with recalls. The technology is showcased in an exclusive video, demonstrating its capabilities across different food sectors, including fruit, vegetable, bakery, and confectionery.

Why It's Important?

The introduction of XMD technology is crucial for the food industry, where contamination can lead to severe financial losses, damaged reputations, and costly recalls. By investing in advanced detection capabilities, food manufacturers can protect their products and uphold brand integrity. This technology not only enhances operational efficiency but also ensures compliance with safety standards, thereby maintaining consumer trust. As plastics often evade traditional metal detection methods, the risk of consumer exposure increases, making the need for such innovative solutions more pressing. Ammeraal Beltech's commitment to developing food-grade conveyor belt solutions reflects the industry's collective responsibility to achieve the highest safety standards.