What's Happening?

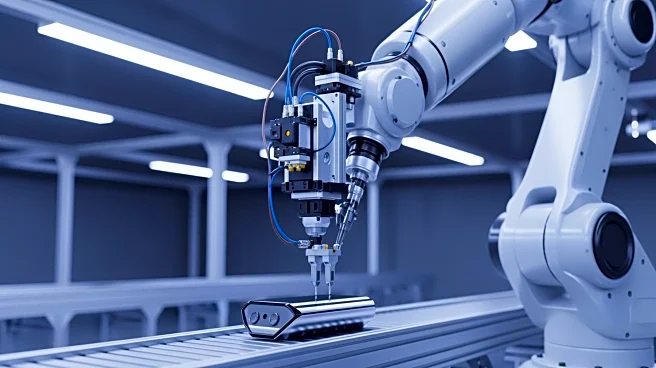

The manufacturing industry is experiencing a transformation with the integration of artificial intelligence (AI). AI tools are now capable of automating design processes, generating CAD code from simple text prompts, and replacing lengthy simulations

with rapid predictions. Companies are increasingly developing custom AI models trained on their own data, enhancing design accuracy and efficiency. This shift is allowing manufacturers to streamline operations and focus on more complex problem-solving tasks. The adoption of AI is expected to become more widespread, with companies integrating AI tools into everyday operations.

Why It's Important?

The adoption of AI in manufacturing is crucial for maintaining competitiveness in a rapidly evolving industry. By automating routine tasks and enhancing design processes, AI can significantly reduce production times and costs. This technological shift could lead to more innovative and customizable products, meeting the growing demand for personalized solutions. As AI becomes more integrated into manufacturing, companies that embrace these changes may gain a competitive edge, while those that lag behind risk falling behind in efficiency and innovation.

What's Next?

In the coming years, AI is expected to become a standard component of manufacturing operations, with more companies developing custom AI models. This trend will likely lead to the creation of unified AI software suites that integrate various workflows, enhancing data security and intellectual property protection. As AI tools continue to evolve, manufacturers will need to adapt to new roles, focusing on oversight and verification of AI-generated designs. The industry will need to balance innovation with precision to ensure high-quality production standards.