What's Happening?

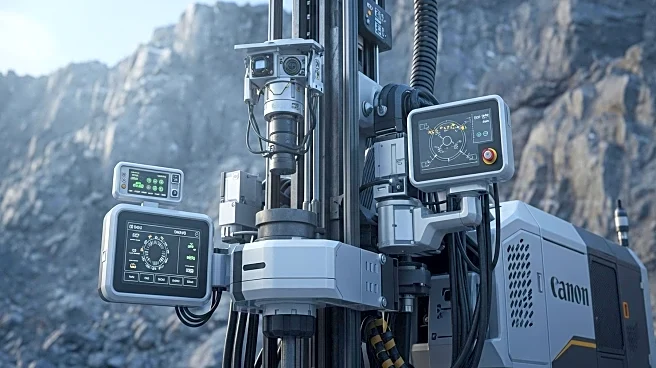

AI-powered predictive maintenance is being adopted by mining companies to address the issue of dirty power, which includes irregularities in electrical supply such as voltage sags and harmonic distortion. These power quality issues can lead to equipment failure and downtime, impacting operational reliability. By continuously monitoring electrical signals, AI systems can detect early signs of mechanical wear, allowing for proactive maintenance and reducing unplanned shutdowns. This approach is particularly beneficial in remote mining locations where power instability is common.

Why It's Important?

The integration of AI in predictive maintenance offers significant advantages for mining operations, including reduced downtime, extended asset life, and lower maintenance costs. By addressing power quality issues early, mining companies can improve operational efficiency and protect high-value assets. This strategic shift towards intelligent maintenance is crucial as mining operations become more digitalized and automated, ensuring clean and reliable power is maintained.

What's Next?

Mining companies are encouraged to start with pilot programs focused on high-value or failure-prone assets to evaluate the benefits of AI-supported maintenance. Partnering with vendors for technical support and training can facilitate the transition and address skill gaps. Ensuring reliable connectivity in remote environments is also critical for successful implementation.