What's Happening?

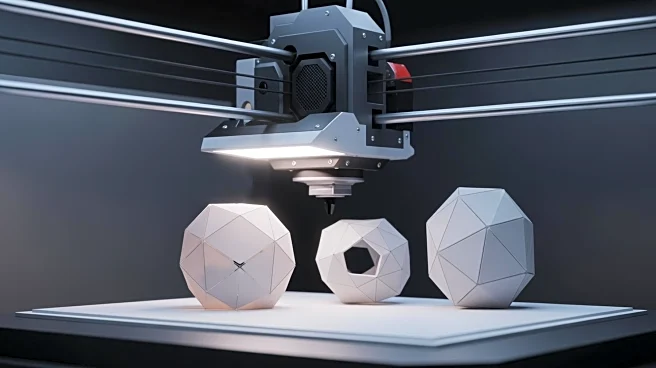

Stratasys has announced a series of innovations across its FDM, SAF, P3 DLP, and software platforms aimed at improving additive manufacturing productivity. The company introduced new materials, faster

print capabilities, and advanced software tools to help manufacturers reduce production time and improve part quality. Key updates include the CoatReady print mode for ULTEM 9085 resin, which enhances surface quality and reduces manual finishing time, and the Nylon 12CF T40 Tip for Fortus 450mc, which nearly doubles build speed for large parts. These advancements are set to be showcased at Formnext 2025 in Frankfurt, Germany.

Why It's Important?

Stratasys' innovations in additive manufacturing are significant for industries such as aerospace, automotive, and consumer products, where efficiency and precision are critical. By expanding material choices and accelerating print speeds, Stratasys is enabling manufacturers to tackle complex applications more efficiently, potentially reducing costs and increasing competitiveness. The introduction of sustainable solutions like ABS TrueRefill also highlights a shift towards environmentally friendly practices in manufacturing, which could influence industry standards and consumer expectations.

What's Next?

Stratasys plans to display these new solutions at Formnext 2025, providing an opportunity for industry stakeholders to explore the latest advancements in additive manufacturing. The company is likely to continue its focus on innovation and operational excellence, potentially leading to further developments in 3D printing technology. As manufacturers adopt these new capabilities, there may be increased demand for Stratasys' products, driving growth in the additive manufacturing sector.

Beyond the Headlines

The advancements by Stratasys reflect broader trends in manufacturing towards automation and sustainability. As industries seek to reduce environmental impact and improve efficiency, technologies like those developed by Stratasys play a crucial role in shaping the future of manufacturing. These developments may also prompt discussions on the ethical implications of automation and the need for workforce adaptation in response to technological changes.