What's Happening?

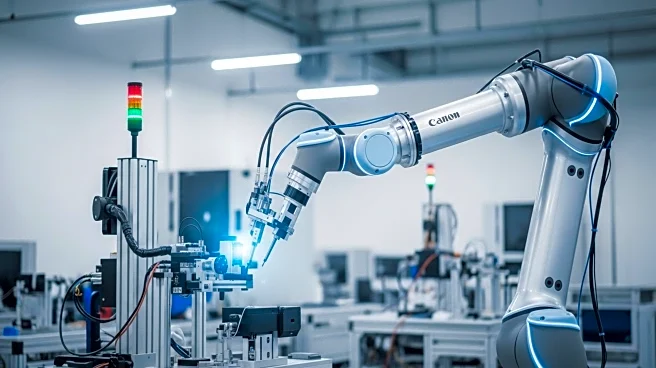

The integration of artificial intelligence (AI) into lean manufacturing processes is being explored as a means to enhance efficiency and problem-solving capabilities. A structured 90-day plan has been proposed to introduce AI in three key areas: problem-solving, quality control, and maintenance. AI is used as a thought partner to improve the quality of problem-solving, detect defects early through AI-enabled systems, and support predictive maintenance. This approach aims to improve business outcomes and customer value by enhancing the clarity of logic in problem-solving, reducing defects, and increasing equipment reliability.

Why It's Important?

The use of AI in lean manufacturing can significantly impact the efficiency and effectiveness of production processes. By improving problem-solving and quality control, manufacturers can reduce waste, lower costs, and enhance product quality. This integration supports the shift from reactive to proactive maintenance, leading to more stable production environments. The strategic use of AI aligns with broader industry trends towards digital transformation and data-driven decision-making, offering competitive advantages to companies that successfully implement these technologies.

What's Next?

As companies begin to implement AI in their lean processes, they are advised to start with small-scale pilots and expand based on successful outcomes. Continuous evaluation and adaptation of AI tools will be necessary to ensure alignment with strategic goals and customer needs. The ongoing dialogue between human operators and AI systems will be crucial in maintaining the balance between technological advancement and human expertise.