What's Happening?

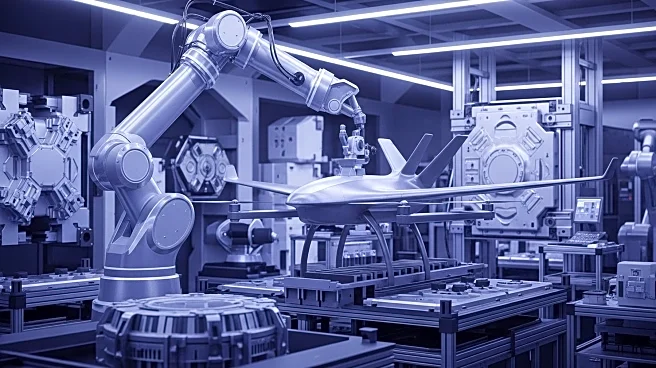

CT UAV has introduced a groundbreaking self-evolving composite molding plant, known as the NAACP-class Composite plant, which is set to transform the manufacturing of unmanned aerial vehicles (UAVs). This facility, located in Ho Chi Minh City, Vietnam, is not just a traditional factory but a complex that integrates science, technology, and services. It specializes in molding fuselages, wings, propellers, and other aircraft parts using advanced materials like Kevlar and Zylon fibers. The plant employs a hybrid process combining automated fiber placement (AFP), infusion, and 3D printing, which accelerates the production of molds and prototypes, reduces R&D costs, and allows for earlier prototype launches. The facility is designed to continuously update and apply cutting-edge science and technology, positioning CT UAV as a leader in the global UAV market.

Why It's Important?

The introduction of the NAACP-class Composite plant by CT UAV marks a significant advancement in UAV manufacturing technology. By utilizing next-generation materials and innovative manufacturing processes, the plant enhances the efficiency and quality of UAV production. This development is crucial for the aerospace industry as it promises to reduce production costs and time, while also improving the mechanical properties of UAVs. The plant's ability to integrate digital simulation, quality control, and AI-driven decision-making further underscores its potential to set new standards in the industry. This could lead to increased competitiveness and innovation in the UAV sector, benefiting both manufacturers and consumers.