What's Happening?

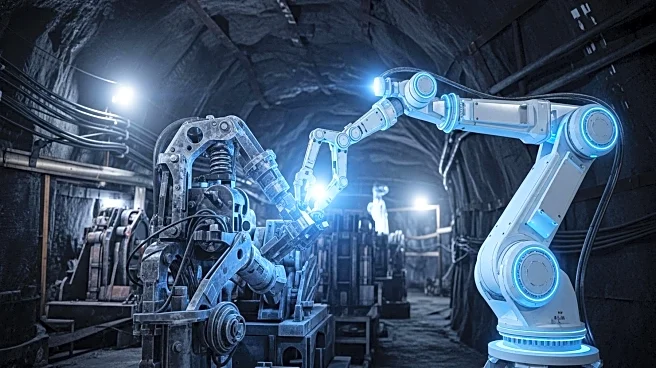

AI-powered predictive maintenance is being increasingly adopted by mining companies to address the issue of dirty power, which refers to irregularities in electrical supply such as voltage sags and harmonic distortion. These power quality issues can lead to equipment failure, erratic performance, and unexpected downtime, posing significant challenges to mining operations. As mining becomes more digitalized, maintaining stable power is crucial for operational reliability. AI systems monitor electrical signals to detect early signs of degradation, allowing for timely interventions before equipment fails. This approach offers advantages over traditional maintenance strategies, which rely on fixed schedules and reactive troubleshooting.

Why It's Important?

The adoption of AI-driven predictive maintenance in mining is significant as it directly contributes to operational efficiency and cost control. By reducing downtime and extending asset life, mining companies can avoid costly unplanned shutdowns and premature equipment retirement. Targeted interventions lower maintenance costs by reducing unnecessary labor and parts usage. Additionally, improved safety is achieved by minimizing equipment failures, which reduces risks to workers and ensures compliance with safety standards. The ability to contextualize electrical anomalies allows mining operators to make informed decisions, enhancing the reliability of complex power systems.

What's Next?

Mining companies considering AI-supported monitoring systems should be aware of potential barriers such as high upfront costs, infrastructure readiness, and workforce skill gaps. Interoperability with existing systems and equipment is crucial, as legacy assets may lack compatibility with modern digital tools. Starting with a pilot program focused on high-value assets can ease the transition. Partnering with vendors for technical support and training can help close skills gaps. Ensuring reliable connectivity, especially in remote environments, is critical for successful implementation. Aligning technology with operational goals and safety standards will be key to achieving long-term benefits.

Beyond the Headlines

The strategic shift towards AI-powered predictive maintenance represents an evolution in mining operations, moving electrical reliability from an afterthought to a core part of production planning. This approach empowers mining companies to focus on preventing problems rather than just fixing them, protecting valuable assets such as equipment, uptime, workforce, and bottom line. By leveraging AI-driven strategies, mining companies can mitigate risks and build more resilient operations, addressing the invisible yet impactful challenges posed by dirty power.