What's Happening?

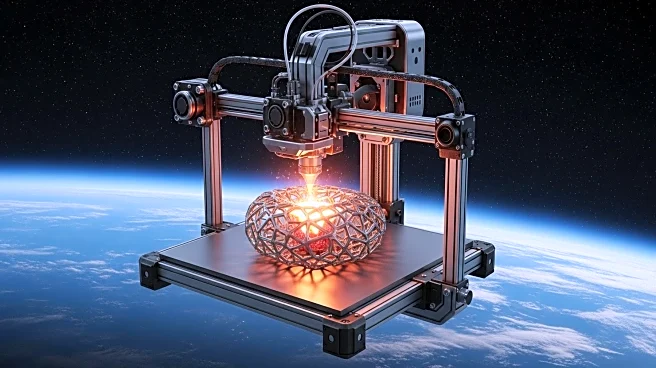

In 2024, the European Space Agency (ESA), in collaboration with Airbus, achieved a significant milestone by printing the first metal object in space using a 3D printer aboard the International Space Station (ISS). This experiment, conducted in the Columbus module, was overseen by astronaut Andreas Mogensen during his Huginn mission. The absence of gravity posed unique challenges, affecting gas flow and thermal solidification during the printing process. Upon returning to Earth, scientists discovered unusual behaviors in the metal's microstructure, prompting further investigation into the implications for future space manufacturing.

Why It's Important?

The ability to 3D print metal objects in space could revolutionize space exploration and manufacturing. This technology allows astronauts to produce tools and components on-demand, reducing the need to launch every item from Earth. This could lead to significant cost savings and increased resilience for missions to the Moon, Mars, and beyond. The experiment highlights the potential for in-orbit manufacturing to improve reliability while conserving mass and volume during launches, according to NASA. The findings could pave the way for a new era of space exploration, where building in space becomes more feasible.

What's Next?

ESA is focusing on refining the printing process, ensuring repeatability, safety, and quality control before approving flight-critical parts. Engineers are working to characterize the microstructure and mechanical performance of the printed objects, aiming to optimize print settings and post-processing steps. The success of this experiment could lead to more advanced manufacturing capabilities in space, potentially supporting satellite repairs and future habitats.

Beyond the Headlines

The experiment raises questions about the long-term implications of manufacturing in microgravity environments. Understanding how microgravity affects material properties could lead to new insights into material science and engineering. This could have broader applications beyond space exploration, potentially influencing manufacturing techniques on Earth.