What's Happening?

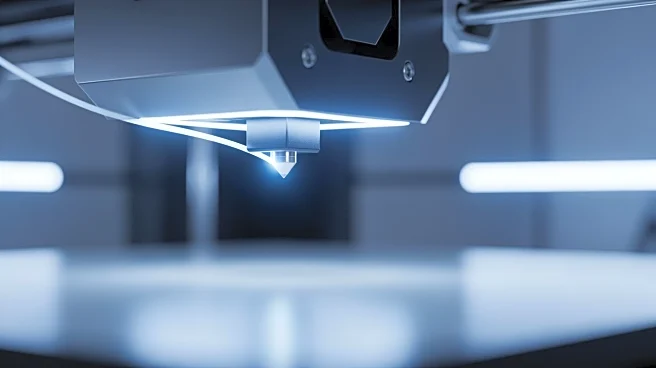

INTAMSYS, a leader in industrial FFF 3D printing, has launched the FUNMAT PRO 310 APOLLO, a next-generation 3D printer designed for high-performance materials. The announcement was made at Formnext, a major

industry event. The new printer is engineered to handle PAEK materials, offering up to four times faster print speeds and over twice the Z-axis strength compared to previous models. It features advanced process control and optimization, dual active-drying filament boxes, RFID material recognition, and the INTAMQuality traceability system. These innovations aim to ensure production consistency and stability, marking a shift from lab-scale to production-scale 3D printing.

Why It's Important?

The launch of the FUNMAT PRO 310 APOLLO represents a significant advancement in the field of industrial 3D printing, particularly for sectors requiring high-performance materials like aerospace, robotics, and automotive. By enabling continuous production with PAEK materials, INTAMSYS is addressing the industry's challenge of achieving consistent material performance at scale. This development could lead to more efficient manufacturing processes, reducing costs and increasing the reliability of parts produced for critical applications. Industries that rely on lightweight, strong, and weather-resistant components stand to benefit significantly from these advancements.

What's Next?

INTAMSYS plans to integrate the FUNMAT PRO 310 APOLLO into smart factories worldwide, potentially transforming manufacturing practices. The company aims to provide scalable, intelligent, and sustainable production solutions, enhancing the capabilities of global manufacturers. As industries adopt this technology, there may be increased demand for high-performance materials, driving further innovation in 3D printing technologies. Stakeholders in aerospace, automotive, and other sectors are likely to monitor the performance and adoption of this new system closely.

Beyond the Headlines

The introduction of the FUNMAT PRO 310 APOLLO could have broader implications for the manufacturing industry, including ethical considerations around automation and job displacement. As production becomes more automated, companies may need to address workforce changes and retraining. Additionally, the environmental impact of increased production capabilities and material usage will be an area of concern, prompting discussions on sustainable practices in industrial manufacturing.