What's Happening?

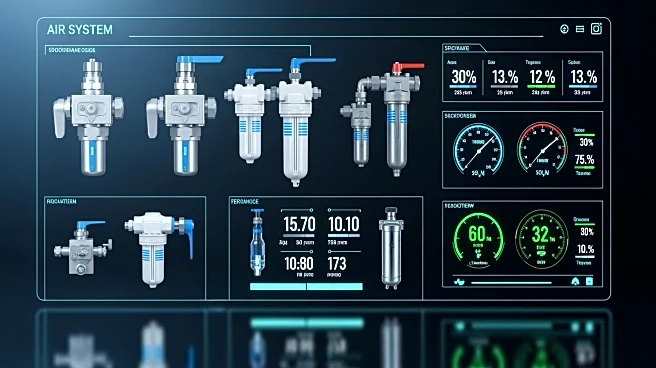

Engineering Sales Associates of the Southeast, Inc. has introduced a free air system self-assessment tool aimed at helping manufacturers in the Charlotte area evaluate the efficiency and reliability of their industrial compressed air systems. The tool is

designed to assist facility managers and maintenance teams in identifying potential issues in their air compressor systems before they lead to production disruptions. It covers critical operational areas such as system pressure requirements, air quality standards, maintenance schedules, and energy consumption patterns. Arthur Pue, President of Engineering Sales Associates, emphasized the importance of the tool in providing a structured approach for facilities to evaluate their current air system performance and identify areas that may require attention. The tool is based on diagnostic criteria used by the company over six decades of servicing industrial clients.

Why It's Important?

The introduction of this self-assessment tool is significant for manufacturers across various sectors, including paper, furniture, food and beverage, textile, pharmaceutical, and automobile production. These industries rely heavily on compressed air for pneumatic tools, process automation, material handling, and quality control applications. By enabling manufacturers to conduct regular system assessments, the tool helps in establishing baseline performance metrics and identifying deviations that may indicate developing problems. This proactive approach can lead to fewer emergency repairs and improved production efficiency, ultimately enhancing competitiveness in the manufacturing sector.

What's Next?

Manufacturers who utilize the self-assessment tool can prepare for consultations with air compressor service providers by documenting system specifications, operating conditions, and maintenance history. This information enables more accurate diagnostics and reduces the time required to resolve issues when professional intervention becomes necessary. Engineering Sales Associates plans to continue supporting manufacturers with comprehensive aftermarket support for all major compressor brands and models.

Beyond the Headlines

The tool reflects lessons learned from thousands of service calls and maintenance interventions, targeting specific failure points encountered in industrial settings. By understanding these risk factors, manufacturers can make informed decisions about maintenance priorities and capital investments, contributing to long-term operational efficiency and sustainability.