What's Happening?

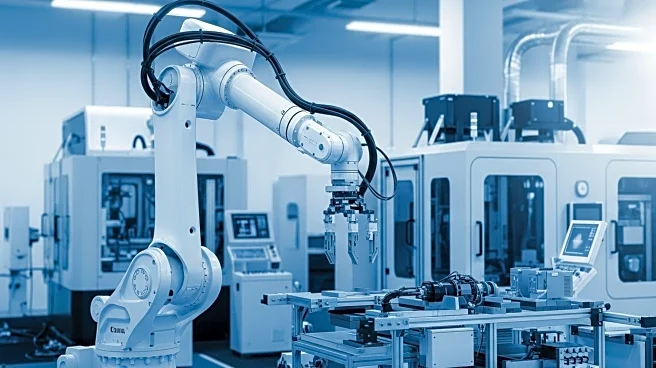

Celanese, a Fortune 500 specialty chemicals company, has implemented a private 5G network at two of its Texas plants in partnership with NTT DATA. This network aims to improve automation, safety, and real-time data flow on the factory floor. The deployment is part of Celanese's Industry 4.0 transformation, providing secure, high-speed connectivity and real-time logistics insights to enhance operational efficiency. The network is fully managed by NTT DATA, which handled site surveys, equipment installation, and cloud-based monitoring. This initiative is expected to provide reliable wireless links for tablets, wearables, sensors, and cameras, even in challenging environments like outdoor chemical plants.

Why It's Important?

The deployment of private 5G networks in manufacturing is significant as it addresses the limitations of traditional Wi-Fi and public cellular networks, which often struggle with interference and connectivity issues in industrial settings. By providing a dedicated cellular system, Celanese can ensure low-latency, high-capacity, and reliable connectivity, crucial for modern 'smart' factories that rely heavily on data and communication. This move is expected to enhance worker safety, operational visibility, and automation, potentially leading to increased productivity and efficiency. The broader adoption of private 5G networks in manufacturing could drive significant growth in the sector, with analysts predicting a substantial increase in spending on these networks.

What's Next?

Celanese's successful deployment of private 5G networks may encourage other manufacturers to adopt similar technologies, potentially leading to widespread Industry 4.0 transformations. As governments and vendors enable more spectrum and service models, the number of enterprise 5G networks is expected to grow significantly worldwide. Celanese plans to extend the network to other sites if the initial rollouts deliver as promised, paving the way for faster, safer, and more automated chemical manufacturing. This trend could also lead to increased collaboration between technology providers and manufacturers to develop tailored connectivity solutions.

Beyond the Headlines

The implementation of private 5G networks in manufacturing not only enhances operational efficiency but also raises questions about cybersecurity and data privacy. As these networks become integral to factory operations, ensuring robust security measures to protect sensitive data and prevent unauthorized access will be crucial. Additionally, the shift towards digital factories may require workforce retraining and adaptation to new technologies, highlighting the need for investment in technical and vocational education to prepare workers for the evolving industrial landscape.