What is the story about?

What's Happening?

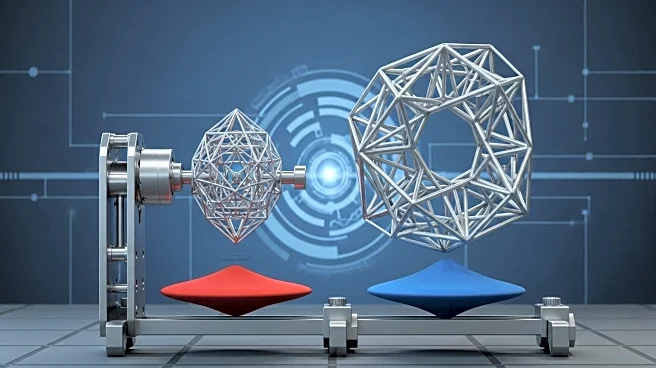

A recent study published in Nature examines the characteristics of spatial 6-degree-of-freedom linear inclined vibrating screens (TLIVS). The research focuses on the amplitude frequency characteristics and the impact of excitation force frequency on the amplitudes of various degrees of freedom. The study uses numerical analysis to solve the steady-state response of TLIVS, revealing resonance phenomena near natural frequencies. The research also includes empirical tests comparing prototype and simulation experiments, showing a screening efficiency difference of 2.4%, validating the dynamic model. The study provides insights into the motion trajectory of the center of mass and the influence of translational and rotational degrees of freedom on material movement.

Why It's Important?

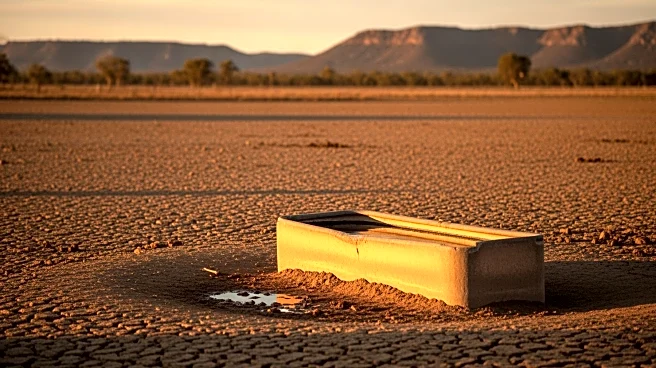

This research is significant for industries relying on vibrating screens for material separation, such as mining and agriculture. Understanding the dynamics of TLIVS can lead to improved screening efficiency, reducing material accumulation and enhancing separation rates. The findings may influence the design and operation of vibrating screens, optimizing performance and minimizing energy consumption. The study's validation of the dynamic model through empirical tests supports its applicability in real-world scenarios, potentially guiding future innovations in screening technology.

What's Next?

The study suggests that further exploration of the coupling effects between different degrees of freedom could enhance screening efficiency. Researchers may focus on optimizing the amplitude and frequency settings to balance screening time and efficiency. Additionally, the application of discrete element methods in simulating different experimental scenarios could provide deeper insights into material behavior, informing the development of more advanced screening systems.

Beyond the Headlines

The research highlights the importance of interdisciplinary approaches, combining mechanical engineering principles with empirical testing to address complex industrial challenges. It underscores the potential for technological advancements in material processing, contributing to sustainability by improving resource utilization and reducing waste. The study may also inspire further research into the application of advanced modeling techniques in other areas of engineering and manufacturing.