What's Happening?

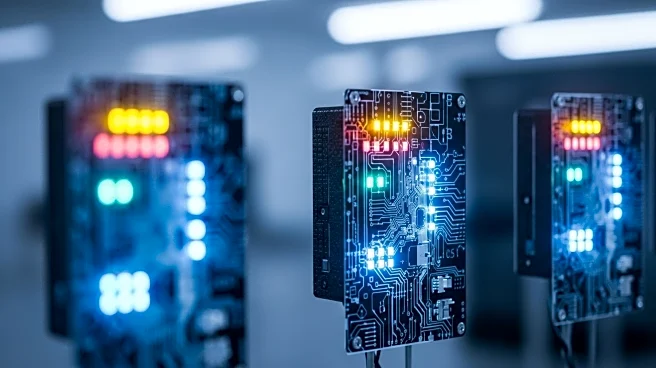

The manufacturing industry is witnessing a significant transformation with the integration of smart sensors, particularly Acoustic Detection and Ranging (ADAR) technology. These sensors provide 3D ultrasound sensing capabilities for robots, priced at approximately $1,000 per unit. This development is part of a broader trend where smart sensors are being increasingly adopted to enhance automation and efficiency in manufacturing processes. The use of ADAR technology allows for precise detection and measurement, which is crucial for improving the accuracy and reliability of robotic operations in industrial settings.

Why It's Important?

The introduction of cost-effective smart sensors like ADAR in manufacturing is pivotal for several reasons. Firstly, it lowers the barrier to entry for smaller manufacturers who may have previously found advanced sensing technology financially prohibitive. This democratization of technology can lead to increased innovation and competitiveness within the industry. Additionally, the enhanced precision and efficiency provided by these sensors can lead to significant cost savings and productivity improvements. As manufacturing processes become more automated and data-driven, the role of smart sensors will be critical in maintaining quality and reducing waste, ultimately benefiting both manufacturers and consumers.

What's Next?

As smart sensor technology continues to evolve, it is expected that more manufacturers will adopt these systems to stay competitive. The ongoing development of even more advanced and affordable sensors could further accelerate this trend. Industry stakeholders, including technology developers and manufacturing companies, are likely to invest in research and development to enhance sensor capabilities and integration. Additionally, there may be increased collaboration between tech companies and manufacturers to tailor sensor solutions to specific industrial needs, potentially leading to new innovations and applications in the field.

Beyond the Headlines

The integration of smart sensors in manufacturing also raises important considerations regarding data privacy and security. As these sensors collect and transmit large amounts of data, ensuring that this information is protected from unauthorized access will be crucial. Moreover, the shift towards more automated systems may impact the workforce, necessitating new skills and training for employees to work alongside advanced technologies. These factors highlight the need for comprehensive strategies to address the ethical and practical implications of increased automation in manufacturing.