What's Happening?

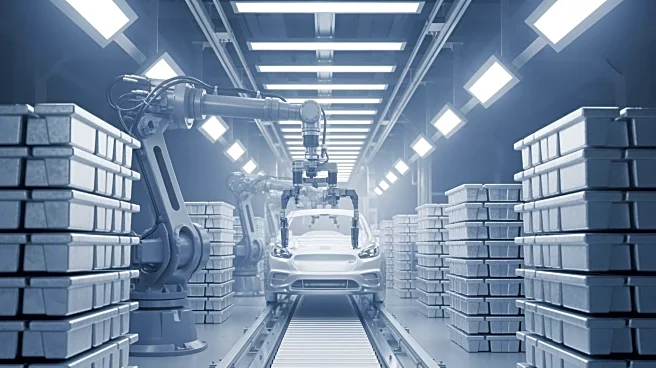

Stellantis is experiencing a production halt at its Warren Truck Assembly plant, where Jeep Wagoneer and Grand Wagoneer vehicles are manufactured. This disruption is due to a parts shortage caused by a fire

at the Novelis aluminum supplier plant on September 16. The fire has affected not only Stellantis but also other automotive manufacturers, including Ford. The idling of the plant is expected to last for three weeks, impacting production schedules and potentially delaying vehicle deliveries.

Why It's Important?

The production halt at Stellantis highlights the fragility of supply chains in the automotive industry, particularly concerning critical components like aluminum. This incident could lead to financial losses for Stellantis and affect its ability to meet consumer demand. The broader impact on the industry includes potential delays in vehicle availability and increased costs for manufacturers. The situation underscores the need for contingency planning and supply chain diversification to mitigate risks associated with supplier disruptions.

What's Next?

Stellantis may need to seek alternative suppliers or adjust production timelines to address the parts shortage. The company could also explore strategies to enhance supply chain resilience, such as diversifying supplier networks or investing in domestic production capabilities. Industry stakeholders are likely to collaborate on solutions to prevent similar disruptions in the future. The incident may prompt discussions on improving safety protocols and risk management practices within supplier operations.

Beyond the Headlines

The fire at the Novelis plant raises questions about the safety and reliability of supplier operations in the automotive industry. It also highlights the interconnectedness of global supply chains and the potential ripple effects of localized incidents. As manufacturers strive to meet consumer demand, they must balance operational efficiency with risk management and sustainability considerations.