What is the story about?

What's Happening?

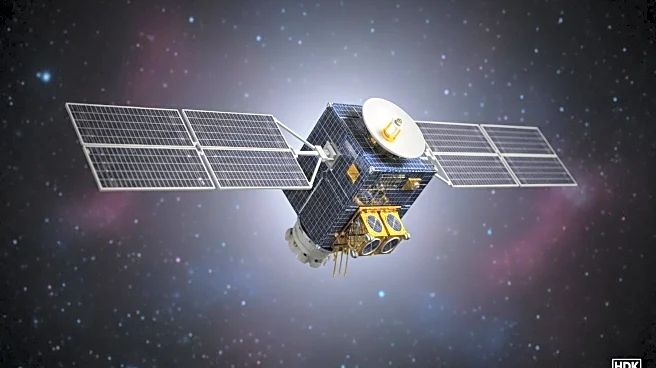

Boeing has announced the implementation of 3D printing technology to manufacture structural panels for satellite solar arrays, aiming to reduce production times by 50%. This initiative is part of Boeing's strategy to meet the increasing demand for rapid spacecraft deployment. The first arrays will be used in small satellites built by Millennium Space Systems, a subsidiary of Boeing. The new manufacturing process allows for parallel assembly with cell production, enhancing speed and consistency through robot-assisted assembly and automated inspection.

Why It's Important?

The adoption of 3D printing in satellite production represents a significant advancement in aerospace manufacturing, potentially reducing costs and increasing efficiency. This move could position Boeing as a leader in the space industry, offering faster deployment of satellites which is crucial for communication, defense, and scientific research. The ability to scale this technology from small to larger satellite platforms could lead to broader applications and market expansion, benefiting industries reliant on satellite technology.

What's Next?

Boeing plans to make this technology available for larger spacecraft platforms by 2026, which could lead to increased production rates and further integration of 3D printing in aerospace manufacturing. The company will likely continue to refine and expand its use of additive manufacturing across its product lines, potentially influencing industry standards and practices.