What's Happening?

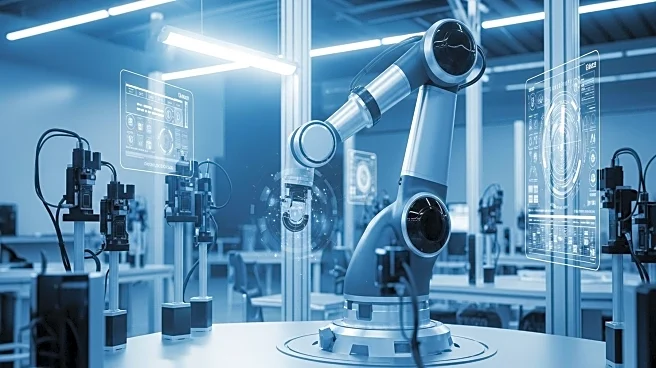

Konica Minolta has unveiled its Intelligent Video Solutions, designed to revolutionize manufacturing processes through smart technology. These systems integrate visual, thermal, sound, and sensor data to automatically monitor and protect people, facilities, and infrastructure. The technology aims to improve efficiency by automating tasks such as visual quality inspection, equipment monitoring, and security management. By leveraging AI, these solutions can detect defects or anomalies in production lines, enhancing quality control and operational efficiency. Additionally, Konica Minolta offers Intelligent Information Management solutions to streamline data handling, breaking down silos and improving access to documents. This digitalization effort is part of a broader push to foster data-driven innovation in manufacturing, enabling businesses to improve product development and operational processes.

Why It's Important?

The introduction of smart technology in manufacturing is crucial for maintaining competitiveness in a global market. By adopting these innovations, manufacturers can achieve significant productivity gains, with reported improvements in production output and capacity. The ability to leverage data effectively allows businesses to enhance efficiency, drive innovation, and improve customer experiences. Furthermore, these technologies help manufacturers comply with regulatory standards and safeguard sensitive information, which is increasingly important in today's data-driven economy. The shift towards digitalization represents a pivotal change, often referred to as the 'Fourth Industrial Revolution,' and is essential for the growth and competitiveness of the manufacturing sector.

What's Next?

Manufacturers are expected to continue integrating smart technologies into their operations, focusing on building more resilient and agile businesses. As these technologies become more widespread, companies will likely invest in further digitalization efforts to streamline processes and reduce costs. The adoption of AI and machine learning will play a significant role in enhancing production quality and operational efficiency. Additionally, manufacturers may explore partnerships with technology providers like Konica Minolta to tailor solutions to their specific needs, ensuring scalability and expert support. The ongoing digital transformation will require businesses to adapt to new opportunities and challenges, positioning themselves for long-term success in the industry.

Beyond the Headlines

The ethical implications of increased automation in manufacturing should be considered, particularly regarding workforce displacement and the need for retraining programs. As businesses adopt more advanced technologies, there may be a shift in the types of skills required, necessitating investment in education and training to prepare workers for new roles. Additionally, the reliance on data-driven decision-making raises concerns about data privacy and security, requiring robust measures to protect sensitive information. The cultural shift towards digitalization may also influence consumer expectations, with increased demand for transparency and efficiency in production processes.