What's Happening?

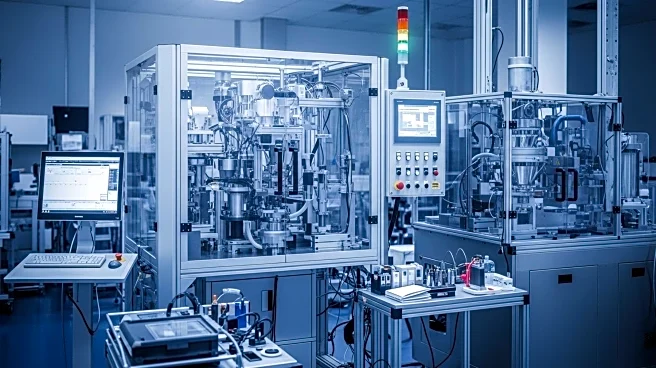

The construction of pharmaceutical facilities in the UK is facing significant challenges due to rework, which can consume up to 20% of construction costs. In environments governed by Good Manufacturing Practice (GMP), rework poses a direct threat to drug delivery timelines and patient outcomes. The systemic issues leading to rework include poor project coordination, complex compliance landscapes, and a shortage of skilled labor. These factors contribute to misalignment between design, engineering, and construction teams, resulting in costly errors and delays. Augmented Reality (AR) is being utilized to mitigate these issues by providing real-time validation and preventing errors from embedding into the build process. AR helps catch deviations early, saving hundreds of program days and accelerating time-to-market for critical medicines.

Why It's Important?

The impact of rework in pharmaceutical construction is profound, affecting not only budgets but also the timely delivery of medicines to patients. Compliance failures can lead to inspection setbacks and suspension of manufacturing licenses, while productivity losses and market share shrinkage can occur due to delays. The use of AR technology offers a proactive solution, reducing preventable rework costs and ensuring vital pharmaceutical products reach patients without avoidable delays. This approach is crucial for maintaining the reputation of companies leading medical innovation and for safeguarding patient outcomes.

What's Next?

The industry must embrace proactive, tech-enabled execution to mitigate the risks associated with rework. Leadership and culture need to align with the mission of 'first-time right' delivery, powered by integrated AR validation. Project leaders must hold teams accountable for precision and break down silos between disciplines. By shifting from a reactive mindset to a proactive one, stakeholders can anticipate and eliminate problems before they impact delivery. This cultural shift, combined with technological advancements, is essential for protecting budgets, ensuring compliance, and keeping vital medicines moving from lab to patient without delay.

Beyond the Headlines

The hidden costs of rework extend beyond budget overruns, affecting productivity and market competitiveness. Delays in drug production can permanently shrink market share, as competitors who deliver faster gain the trust of healthcare providers and investors. The integration of AR technology not only reduces rework costs but also bridges the skill shortage gap and aligns disciplines more tightly, reducing the risk profile of projects. This technological and cultural transformation is necessary to meet the high standards of pharmaceutical construction and to ensure the timely delivery of life-saving medicines.