What's Happening?

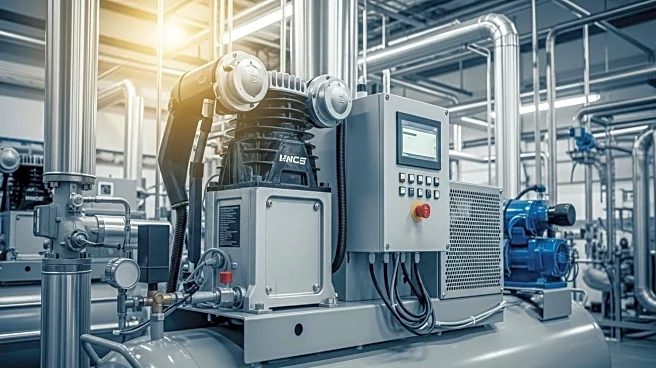

A major UK dairy desserts manufacturer has achieved significant energy savings and enhanced production capabilities by upgrading its compressed air system with Atlas Copco's latest oil-free technology. The upgrade has resulted in an annual electricity cost reduction of £117,000 and carbon savings of over 1,300 tonnes of CO2. The manufacturer, known for its custard and rice pudding, previously faced challenges with outdated compressors that risked production capacity and compliance with air quality standards. Atlas Copco conducted a comprehensive audit, leading to the installation of three ZR 160 VSD+ FF compressors, which provide 100% oil-free air and meet the highest purity standards for food applications. The new system also includes advanced monitoring and energy recovery features, further enhancing efficiency and sustainability.

Why It's Important?

This development is significant as it highlights the potential for industrial upgrades to deliver substantial cost savings and environmental benefits. By adopting Atlas Copco's oil-free technology, the dairy desserts manufacturer not only reduces operational costs but also strengthens its sustainability credentials. The move underscores the importance of modernizing industrial systems to meet stringent quality standards and reduce carbon footprints. This case could serve as a model for other food and beverage producers seeking to enhance efficiency and sustainability while maintaining product quality and safety.

What's Next?

The successful implementation of Atlas Copco's technology positions the dairy desserts manufacturer for future growth. With improved air quality and production security, the company can expand its output without compromising on safety or quality. The integration of advanced monitoring systems and energy recovery units also supports ongoing efficiency improvements and Industry 4.0 integration. As the food industry continues to prioritize sustainability, similar upgrades may become more common, driving broader environmental and economic benefits.

Beyond the Headlines

The upgrade reflects a broader trend towards sustainability and efficiency in the food industry. By eliminating the risk of oil contamination and reducing energy consumption, the manufacturer not only protects its brand reputation but also aligns with increasing consumer demand for environmentally responsible practices. This shift towards cleaner, more efficient production methods could influence regulatory standards and consumer expectations, prompting further innovation and investment in sustainable technologies.