What is the story about?

What's Happening?

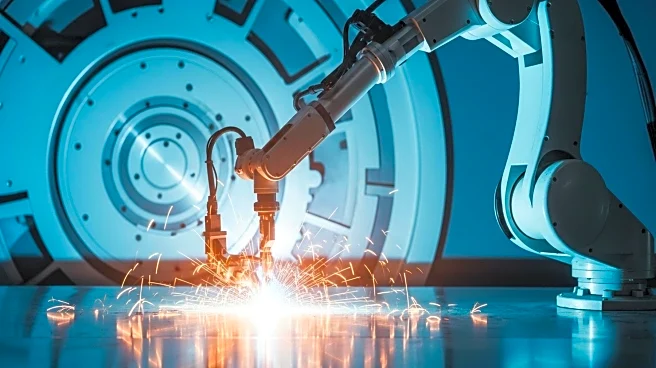

Miller Electric is hosting a webinar to discuss the impact of welding automation on profitability, worker engagement, and operational efficiency. The event will feature insights from industry experts, including David Schaefer, an Automation Sales Specialist with over 20 years of experience in robotic welding sales. The discussion will focus on the challenges and benefits of transitioning from manual to robotic welding, emphasizing the importance of understanding the entire process, including upstream part preparation, tooling, and layout. The webinar aims to provide practical guidance on evaluating the return on investment (ROI) of automation beyond financial metrics, considering factors such as workforce impact and long-term scalability.

Why It's Important?

The adoption of welding automation is crucial for manufacturers seeking to enhance productivity and quality while addressing labor shortages. By transitioning to robotic welding, companies can attract younger workers and improve retention, as modern technology appeals to the new generation. Automation also offers consistent quality and productivity gains, enabling businesses to grow without relying on a shrinking pool of skilled welders. Understanding the broader implications of automation, including its impact on workforce engagement and operational efficiency, is essential for manufacturers aiming to remain competitive in the industry.

What's Next?

Manufacturers considering automation must overcome the fear of failure and investment risk by starting smart, aligning expectations, and planning for scalability. The webinar will encourage participants to view ROI through a broader lens, considering not only financial returns but also the ability to grow and adapt to changing workforce dynamics. As companies explore automation, they will need to account for factors such as part preparation and tooling to maximize the benefits of new equipment.

Beyond the Headlines

The shift to automation in welding presents ethical and cultural dimensions, as it requires a change in mindset from traditional hand welding techniques. Companies must navigate the transition carefully to avoid inefficiencies and retraining challenges. Additionally, the integration of automation technology can lead to long-term shifts in workforce demographics, as younger workers are drawn to modern tech environments.