What's Happening?

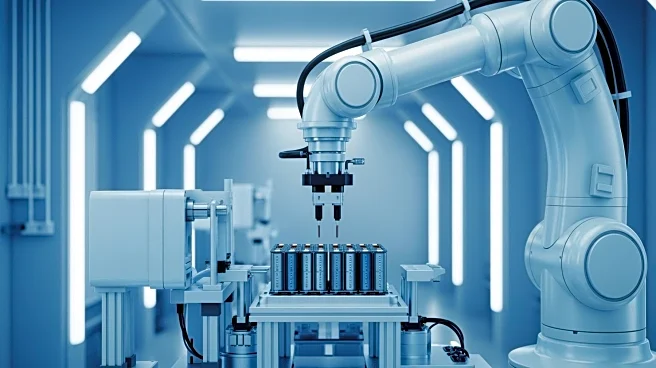

The University of Birmingham's Energy Materials Group has implemented TIDAS technology to improve the precision of battery manufacturing. This system provides early measurements of agglomerate size in battery electrode slurries, preventing the use of uncoatable

slurries and enhancing particle dispersion. The technology has increased efficiency and reduced waste in the production process, offering significant time and material savings. TIDAS is particularly beneficial in ensuring the quality of slurry mixtures, which are crucial for effective electrode coating and consistent battery performance.

Why It's Important?

The adoption of TIDAS technology represents a significant advancement in battery manufacturing, addressing challenges related to slurry quality and consistency. By improving the precision of the manufacturing process, this technology can enhance the performance and lifespan of batteries, which are critical components in various industries, including electric vehicles and renewable energy. The reduction in waste and increased efficiency also contribute to more sustainable manufacturing practices.

What's Next?

The University of Birmingham plans to continue exploring the potential of TIDAS technology in other areas of battery research and manufacturing. As the demand for high-performance batteries grows, this technology could play a key role in meeting industry needs and driving innovation. Collaboration with industry partners may lead to further developments and the integration of TIDAS into commercial production lines.

Beyond the Headlines

The implementation of TIDAS technology highlights the importance of precision and quality control in advanced manufacturing processes. It underscores the role of academic research in driving technological innovation and the potential for such advancements to transform industries. The focus on sustainability and efficiency aligns with broader trends towards environmentally responsible manufacturing practices.