What is the story about?

What's Happening?

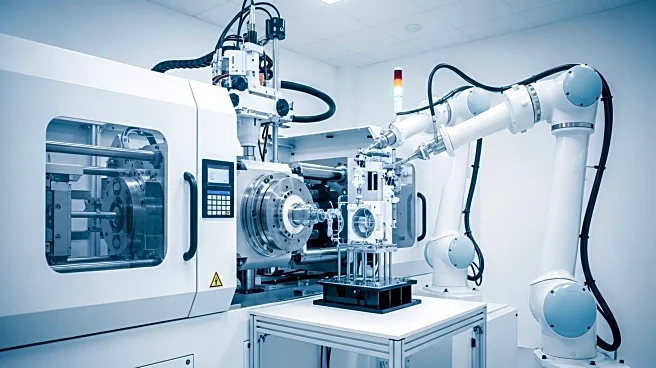

Kistler is set to showcase its AI-supported automated quality control system for injection molding in the medical technology sector at the K 2025 event in Düsseldorf. This system represents a shift from traditional random sampling to automated 100 percent inspection, ensuring each part meets quality standards. The technology utilizes data from sensors embedded in the molding tools to calculate key product characteristics, such as dimensions and weight, using AI models. This innovation is crucial for the medical device industry, which faces increasing demand for reliable products like auto-injectors, necessitating rapid production ramp-ups without compromising quality.

Why It's Important?

The implementation of AI-driven quality control in injection molding is a significant advancement for the medical technology industry. It ensures higher safety standards and reliability for medical devices, which is critical given the life-threatening consequences of device malfunctions. This technology allows manufacturers to provide proof of exhaustive technical measures to prevent errors, potentially reducing liability risks. Moreover, it supports the industry's need for rapid production increases to meet growing demand, while maintaining compliance with stringent FDA and MDR standards. This shift could lead to broader adoption of AI in quality assurance across various sectors.