What's Happening?

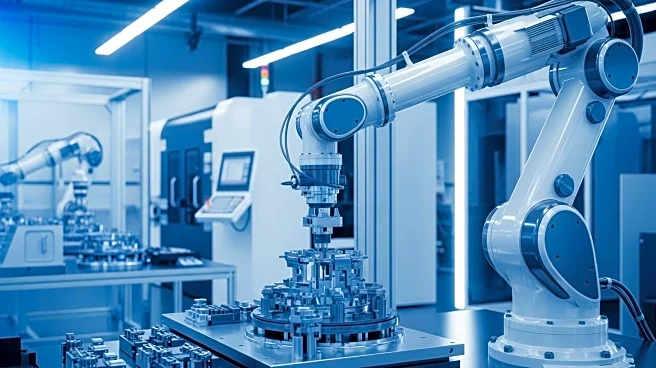

Pre-Met has invested £500,000 to relocate the operations and welding technology of Quality Springs & Pressings (QSP), a business acquired earlier this year. The relocation includes upgrading the factory-wide electrical supply, freeing up 10,000 sq. ft. of production space, and creating dedicated welding bays. This move aims to capitalize on enhanced wire form and spring manufacturing expertise, embedding robotic welding and assemblies into its service offerings. The relocation has already created four new jobs, with potential for more as Pre-Met secures new work in transportation, electronics, and construction products. The company has also obtained JOSCAR approval, a global best practice supplier portal used by major OEMs and supply chain companies.

Why It's Important?

The investment and relocation by Pre-Met signify a strategic expansion in its manufacturing capabilities, particularly in the defense, aerospace, and transportation sectors. By enhancing its production facilities and securing new accreditations, Pre-Met is positioning itself as a critical supplier in these industries. The creation of new jobs and the potential for further employment growth highlight the positive economic impact on the local community. Additionally, the acquisition and subsequent investment reflect a broader trend of companies seeking to modernize and expand their operations to meet increasing demand and technological advancements.

What's Next?

Pre-Met plans to continue its expansion by participating in industry events, such as the virtual Made in the Midlands event and the Farnborough 'JOSCAR' meet the buyer session. These events provide opportunities to engage with defense buyers and explore new market entries. The company is also focused on further modernizing its production facilities and enhancing its service offerings, which may lead to additional job creation and business growth.

Beyond the Headlines

The relocation and investment by Pre-Met underscore the importance of digital transformation and technological integration in manufacturing. By embedding robotic welding and assemblies, the company is not only improving efficiency but also setting a precedent for other manufacturers to follow suit. This move may influence industry standards and encourage other companies to adopt similar practices to remain competitive.