What is the story about?

What's Happening?

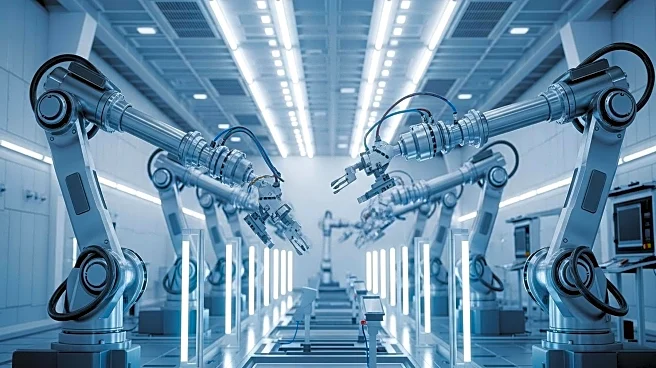

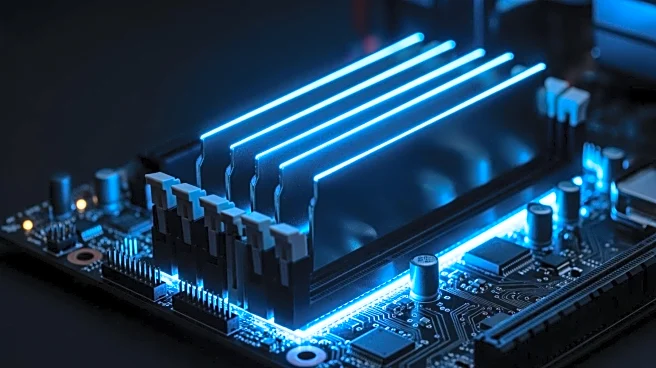

The manufacturing industry is undergoing a significant transformation with the advent of smart factories, driven by Industry 4.0 and the emerging Industry 5.0. These developments are characterized by the integration of digital technologies, automation, and data intelligence to optimize production processes, enhance productivity, and address labor shortages. Industry 5.0 further emphasizes human-centered values, aiming to improve worker experiences and create broader societal impacts. Heilind Electronics is at the forefront of this evolution, offering cutting-edge connector solutions that facilitate high-speed data transmission, reliable power delivery, and compact design, essential for modern industrial applications. The eBook 'Empowering Smart Factories' by Hirose Electric, available through Heilind Electronics, explores the role of advanced connector solutions in supporting the transition to smart manufacturing, highlighting their applications in sectors such as robotics, drones, and industrial sensors.

Why It's Important?

The shift towards smart factories is crucial for the manufacturing sector as it seeks to enhance efficiency, reduce waste, and overcome labor shortages. By integrating advanced technologies, manufacturers can streamline operations and improve decision-making processes. The adoption of Industry 5.0 principles, which focus on human-centered values, is expected to improve worker satisfaction and contribute to societal benefits. Companies like Heilind Electronics and Hirose Electric are playing a pivotal role by providing innovative connector solutions that support these advancements. This transformation is likely to lead to increased competitiveness in the manufacturing industry, driving economic growth and sustainability. Manufacturers that embrace these changes stand to gain significantly in terms of productivity and resource optimization.

What's Next?

As smart factories continue to evolve, manufacturers are expected to further integrate digital technologies and automation into their operations. The focus will likely shift towards enhancing human-machine collaboration, improving worker experiences, and achieving sustainable production practices. Companies providing advanced connector solutions, like Heilind Electronics and Hirose Electric, will continue to innovate to meet the demands of Industry 4.0 and 5.0. Stakeholders in the manufacturing sector may need to invest in training and development to equip workers with the skills necessary to thrive in this new environment. Additionally, there may be increased collaboration between technology providers and manufacturers to develop customized solutions that address specific industry challenges.

Beyond the Headlines

The transition to smart factories not only impacts the manufacturing industry but also has broader implications for society and the environment. By prioritizing sustainability and efficiency, these advancements contribute to reduced environmental impact and resource optimization. The focus on human-centered values in Industry 5.0 may lead to improved workplace conditions and employee satisfaction, potentially influencing labor policies and practices. Furthermore, the integration of advanced technologies in manufacturing could drive innovation in other sectors, such as logistics and supply chain management, leading to more efficient and sustainable business models.