What is the story about?

What's Happening?

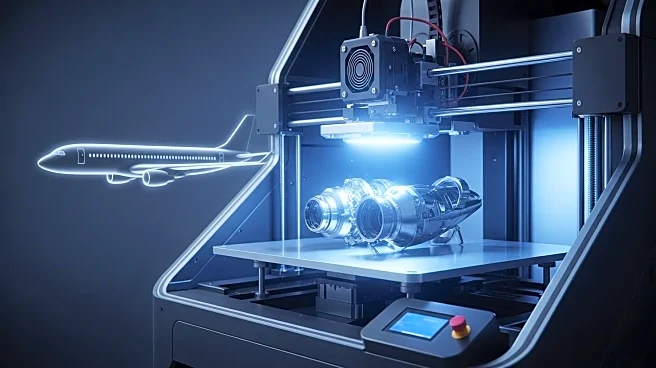

Spectrum Networks, LLC and ALOFT AeroArchitects have adopted Markforged's FX10 composite 3D printing systems to produce certified, flight-ready components for VIP and government aircraft. This technology allows for the rapid production of replacement parts, significantly reducing lead times from months to weeks. The parts are manufactured using Continuous Fiber Reinforcement (CFR) technology, which enhances their structural integrity and surface finish. In 2024, Spectrum Networks produced over 10,000 certified flight parts, aiding in the modernization of aircraft interiors and maintaining operational readiness. The parts undergo automated laser micrometer inspection, generating conformance reports that facilitate regulatory acceptance by the FAA and global aviation authorities.

Why It's Important?

The adoption of Markforged's technology by Spectrum Networks and ALOFT AeroArchitects represents a significant advancement in the aerospace industry, particularly in the maintenance and modernization of aircraft used by world leaders and governments. By reducing lead times and improving part precision, this technology enhances the reliability and efficiency of aircraft operations. The ability to produce parts on demand addresses supply chain challenges and obsolescence issues, offering a strategic advantage in maintaining critical fleets. This development also underscores the growing importance of additive manufacturing in aerospace, potentially setting new standards for safety, quality, and performance.

What's Next?

As the technology continues to prove its efficacy, it is likely that more aerospace manufacturers will adopt similar additive manufacturing solutions to streamline their operations. The collaboration between Spectrum Networks and ALOFT AeroArchitects may inspire further innovations in aircraft maintenance and part production, potentially leading to broader regulatory acceptance and integration into more aircraft systems. The ongoing development of Markforged's technology could also expand its application beyond aerospace, influencing other industries that require high-precision, durable components.

Beyond the Headlines

The use of Markforged's technology highlights the ethical and environmental considerations of adopting additive manufacturing in aerospace. By reducing waste and improving efficiency, this approach aligns with sustainable manufacturing practices. Additionally, the technology's ability to produce parts with digital traceability and continuous fiber reinforcement may set new benchmarks for quality assurance and regulatory compliance in the industry.