What's Happening?

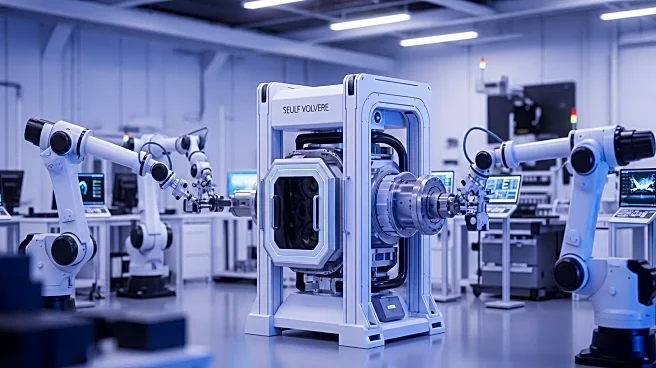

CT UAV has introduced a groundbreaking self-evolving composite molding plant, known as the Next-Generation Aerospace Advanced Composite Plant (NAACP), in Ho Chi Minh City, Vietnam. This facility is designed to produce advanced composite materials for unmanned aerial vehicles (UAVs), including fuselages, wings, and propellers. The plant emphasizes automation and digital simulation, utilizing technologies such as AFP/ATL robots and digital twins to optimize production processes. It integrates AI-driven quality control systems and a comprehensive value chain from research and development to product lifecycle logistics. The facility aims to innovate beyond traditional carbon fiber processing by incorporating advanced materials like Kevlar and Zylon fibers.

Why It's Important?

The establishment of the NAACP-class composite molding plant marks a significant advancement in aerospace manufacturing, particularly for UAVs. By leveraging cutting-edge technologies and materials, CT UAV is poised to enhance the efficiency and precision of aerospace component production. This development could lead to reduced production costs and faster prototype launches, benefiting the aerospace industry globally. The integration of AI and machine learning for defect detection and predictive maintenance further underscores the plant's potential to set new standards in quality assurance. As the aerospace sector continues to grow, innovations like these are crucial for maintaining competitive advantage and meeting increasing demand for advanced UAV technologies.

What's Next?

CT UAV's new plant is expected to drive further innovation in aerospace manufacturing, potentially influencing industry standards and practices. The facility's focus on automation and AI could lead to increased adoption of similar technologies across the sector. As the plant continues to evolve, it may expand its capabilities to include more advanced composite materials and manufacturing techniques. Stakeholders in the aerospace industry, including manufacturers and suppliers, will likely monitor the plant's progress and consider integrating similar technologies to enhance their own production processes. The plant's success could also encourage investment in similar facilities worldwide.

Beyond the Headlines

The introduction of the NAACP-class composite molding plant highlights the growing importance of sustainable and efficient manufacturing practices in the aerospace industry. By utilizing green composites and bio-resins, CT UAV is addressing environmental concerns associated with traditional manufacturing processes. The plant's emphasis on digital twin technology and IoT sensors reflects a broader trend towards smart manufacturing, which could lead to more sustainable and resource-efficient production methods. Additionally, the plant's focus on AI-driven decision-making and quality control may prompt discussions on the ethical implications of increased automation in manufacturing.