What's Happening?

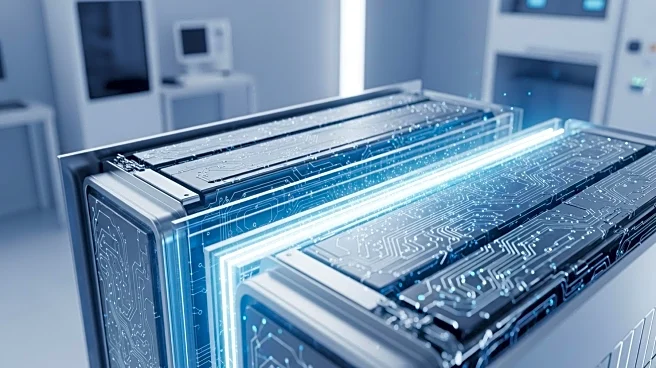

Electroflow, a U.S.-based startup, is set to revolutionize the production of lithium-iron-phosphate (LFP) materials by significantly reducing costs. The company plans to scale its production to achieve a cost of less than $2,500 per metric ton by the end of the year, which is 40% lower than current Chinese production costs. This initiative is part of Electroflow's strategy to establish a domestic supply chain for LFP materials, which are crucial for electric vehicle batteries. The company has developed a three-step process to transform salty water into LFP material, which is more efficient than traditional methods. Electroflow's system, which will be housed in a 20-foot shipping container, is expected to produce 100 metric tons of LFP material annually.

Why It's Important?

This development is significant for the U.S. electric vehicle industry, which is heavily reliant on Chinese LFP materials. By reducing production costs and establishing a domestic supply chain, Electroflow could enhance the competitiveness of U.S. automakers. The move also aligns with broader efforts to reduce dependency on foreign materials and strengthen national security. Additionally, the environmental benefits of Electroflow's process, which uses minimal electricity and water, could appeal to stakeholders focused on sustainable manufacturing practices.

What's Next?

Electroflow plans to complete its full-scale production system by the end of the year. The company has already secured a $10 million seed round to support its expansion. As Electroflow scales up, it may face competition from Chinese producers who could innovate to lower their costs. However, if successful, Electroflow's model could inspire similar initiatives in other sectors reliant on imported materials.