What's Happening?

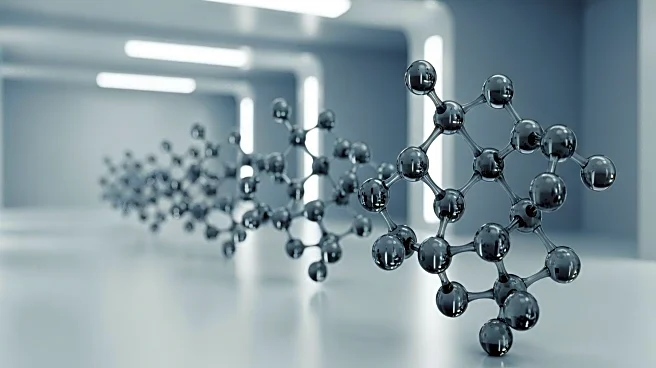

Monoclonal antibody intermediates are crucial components in the manufacturing of precision medicines, specifically antibody-drug conjugates. These intermediates require precise engineering and controlled handling to ensure compatibility with linker-payload complexes. The process involves several stages, including conjugation, purification, and formulation, each presenting unique challenges in preserving product quality, operator safety, and process efficiency. Advanced technologies in mixing, filtration, and purification are employed to reduce impurities, enhance yields, and streamline bioprocessing, ensuring the integrity of the final product.

Why It's Important?

The manufacturing of precision medicines, such as antibody-drug conjugates, is significant for the pharmaceutical industry as it represents a growing sector focused on targeted therapies. These medicines offer potential benefits in treating various diseases, including cancer, by delivering drugs directly to affected cells, minimizing side effects. The challenges in manufacturing these intermediates highlight the need for continued innovation and investment in bioprocessing technologies. Successful production can lead to improved patient outcomes and drive advancements in personalized medicine, impacting healthcare providers, patients, and pharmaceutical companies.