What's Happening?

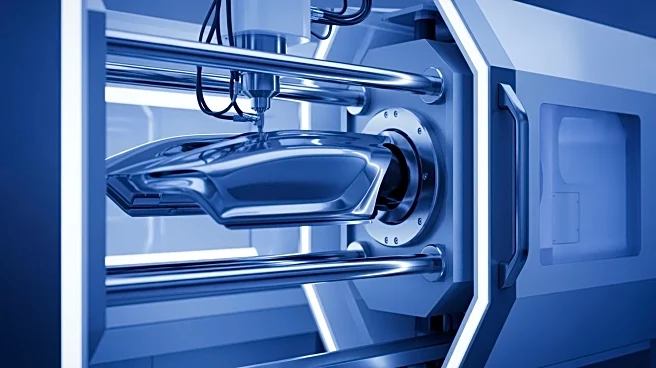

Toyoda Gosei, in collaboration with Kansai Paint, has developed an innovative in-mold coating technology for large plastic automotive parts. This technology allows parts to be formed and painted inside

molds, marking the first time such a process is applicable to mass production of large exterior parts in Japan. The new method eliminates the need for drying furnaces, significantly reducing carbon dioxide emissions by approximately 60%. The technology also enhances the durability of the painted surface, making abrasions less visible. Large painted products using this technology are expected to launch in the market by spring 2026, with plans for implementation at Toyoda Gosei's international production sites.

Why It's Important?

The introduction of this in-mold coating technology is significant for the automotive industry as it addresses environmental concerns by reducing carbon emissions during production. This aligns with global efforts to minimize the automotive sector's carbon footprint. The technology not only supports sustainable manufacturing practices but also enhances product durability and design flexibility. As the industry faces increasing pressure to adopt eco-friendly technologies, Toyoda Gosei's innovation could set a precedent for other manufacturers, potentially influencing industry standards and practices.

What's Next?

Toyoda Gosei and Kansai Paint plan to continue their collaboration to expand the application of this technology to a broader range of products. This ongoing development could lead to further reductions in emissions and advancements in vehicle design. The successful implementation of this technology at international production sites will be crucial in determining its global impact. Stakeholders in the automotive industry, including manufacturers and environmental groups, will likely monitor these developments closely.