What's Happening?

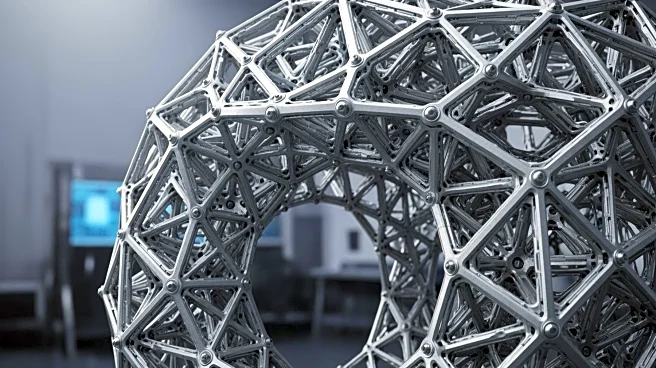

Researchers at the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland have developed a new method to create 3D-printed metal structures that are 20 times stronger than those produced by traditional

methods. This breakthrough utilizes a process known as vat photopolymerization, which typically uses light-reactive resin to form intricate structures. The new technique involves creating a lattice from hydrogel, soaking it in metal salts, and infusing it with metal nanoparticles. After repeating this process multiple times, the hydrogel is removed, leaving behind a dense and strong metallic structure. This advancement addresses the common issue of shrinkage and warping in vat photopolymerization, enhancing the strength and quality of the metal components.

Why It's Important?

The development of stronger metal structures through advanced 3D printing techniques has significant implications for various industries, including aerospace, automotive, and electronics. By overcoming the limitations of traditional vat photopolymerization, this method could lead to the production of more durable and reliable components, potentially reducing costs and improving performance. The ability to create high-quality metals and ceramics with a low-cost 3D printing process could revolutionize manufacturing, making it more accessible and efficient. Industries that rely on complex metal components stand to benefit from this innovation, as it could lead to advancements in product design and functionality.

What's Next?

The researchers are working on reducing the processing time required for this new method by automating the infusion steps with robotics. This could make the technique more appealing to industries by addressing the current time-consuming nature of the process. As the method becomes more efficient, it may see wider adoption in manufacturing sectors, potentially leading to further innovations in 3D printing and material science. The ongoing development and optimization of this technique could pave the way for new applications and improvements in the production of metal components.

Beyond the Headlines

This breakthrough in 3D printing technology highlights a shift in additive manufacturing, where material selection occurs after the printing process rather than before. This paradigm change could lead to new approaches in manufacturing, allowing for greater flexibility and customization in material properties. The ability to 'grow' metal structures with enhanced strength may also inspire further research into other materials and applications, potentially leading to advancements in fields such as nanotechnology and biomaterials.