What's Happening?

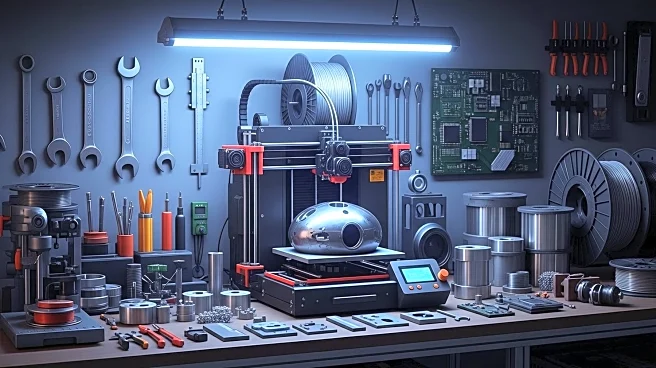

The U.S. Navy is increasing its reliance on additive manufacturing, commonly known as 3D printing, to mitigate supply chain delays affecting its submarine programs. Lincoln Electric, a prominent welding equipment manufacturer, is playing a crucial role in this initiative by producing 3D-printed parts for submarines. This move is part of the Navy's Maritime Industrial Base Program, which aims to accelerate the construction and delivery of Virginia-class and Columbia-class nuclear submarines. Lincoln Electric's facility in Cleveland will manufacture critical components using large-scale wire arc additive manufacturing printers, marking the company's largest government-backed investment in this technology. The decision to utilize 3D printing stems from its ability to reduce lead times for complex parts, despite higher per-unit costs compared to traditional casting methods.

Why It's Important?

The adoption of additive manufacturing by the U.S. Navy is significant as it addresses persistent supply chain bottlenecks that have delayed submarine construction. By leveraging 3D printing, the Navy aims to enhance the speed and quality of submarine production, which is crucial for maintaining its naval capabilities. This technological shift could set a precedent for other military and industrial applications, potentially transforming manufacturing processes across various sectors. The initiative also highlights the strategic importance of ensuring material availability and reducing dependency on traditional manufacturing methods, which can be slower and less adaptable to changing demands.

What's Next?

As the U.S. Navy scales up its use of additive manufacturing, it is expected to closely monitor the performance and reliability of 3D-printed components in submarines. The success of this initiative could lead to broader adoption of 3D printing in other areas of military and industrial manufacturing. Stakeholders, including defense contractors and technology firms, may explore further collaborations to expand the use of additive manufacturing in defense applications. Additionally, the Navy's focus on reducing lead times and improving supply chain efficiency may prompt other branches of the military to consider similar technological advancements.

Beyond the Headlines

The shift towards additive manufacturing in submarine production may have long-term implications for the defense industry, including potential changes in workforce skills and training requirements. As 3D printing becomes more integral to manufacturing processes, there may be increased demand for expertise in digital design and production technologies. This transition could also influence environmental sustainability in manufacturing, as additive processes often generate less waste compared to traditional methods. Furthermore, the success of this initiative could encourage other industries to adopt similar technologies, potentially leading to broader economic and technological shifts.