What's Happening?

Dymax, a global manufacturer of light-curing materials and equipment, is set to exhibit its latest innovations at the SMTA International 2025 event in Rosemont, Illinois, from October 21 to 23. The company

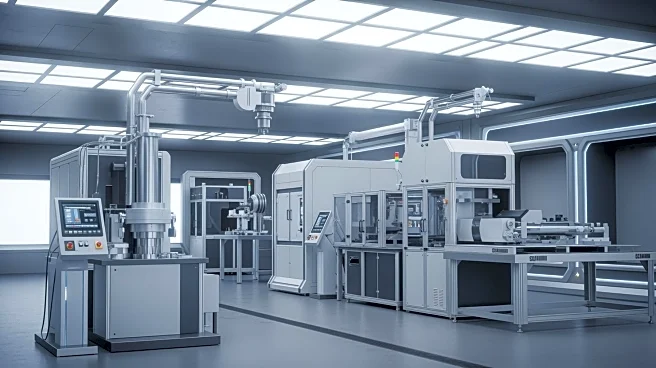

will highlight its solutions designed to address electronics assembly challenges, focusing on protecting components from harsh environments and streamlining assembly workflows. Key products include TPO-free UV/LED-curable materials such as the 9501-F-Z adhesive and the 7501-T-UR-SC-Z coating, formulated to comply with evolving regulations and meet customer demand for TPO-free options in battery and PCB assemblies. Dymax will also showcase conformal coatings and maskants designed to protect PCBs and critical electronics against heat, corrosive chemicals, and moisture. Additionally, the BlueWave QX4 V2.0 LED spot-curing system and PVA Delta-8 selective coating and dispensing system will be featured to demonstrate precise curing and programmable dispensing capabilities.

Why It's Important?

The exhibition of Dymax's advanced materials and equipment at SMTA International 2025 is significant for the electronics manufacturing industry, as it addresses critical assembly challenges and regulatory compliance. By offering TPO-free options, Dymax supports manufacturers in meeting stringent environmental regulations while enhancing product reliability and performance. The showcased technologies aim to reduce cycle times and increase throughput, which is crucial for manufacturers seeking efficiency and cost-effectiveness in production processes. Dymax's focus on improving reliability and long-term product performance aligns with industry demands for high-quality, durable electronics components, potentially benefiting sectors such as avionics, automotive, and industrial applications.

What's Next?

Technical experts from Dymax will be available at the event to provide guidance on product selection, curing-process design, and reliability considerations for PCB and board-level projects. This interaction is expected to foster collaboration and innovation within the electronics manufacturing community, as manufacturers seek solutions to enhance their assembly processes. The event may also lead to increased adoption of Dymax's technologies across various sectors, as companies look to improve their production capabilities and comply with regulatory standards.

Beyond the Headlines

The emphasis on TPO-free materials reflects a broader industry trend towards environmentally friendly manufacturing practices. As regulations continue to evolve, companies like Dymax are at the forefront of developing solutions that not only meet compliance requirements but also enhance product performance. This shift towards sustainable manufacturing could have long-term implications for the industry, influencing product design and material selection in the future.