What's Happening?

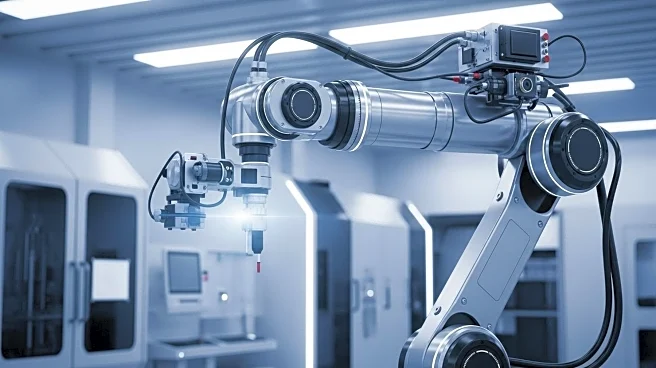

A leading global automotive manufacturer has successfully implemented Senseye Predictive Maintenance across its operations in 20 countries. This strategic move was driven by the need to manage extensive sensor data with limited skilled resources. The implementation has resulted in significant achievements, including monitoring over 10,000 machines across 100 different types, achieving a return on investment in less than three months, and providing a six-month advance warning of potential failures. The initiative has also led to a substantial reduction in preventive maintenance costs and continuous improvements in Overall Equipment Effectiveness (OEE). The solution has empowered over 500 active users to optimize maintenance processes autonomously, allowing engineers to onboard new machines and integrate with enterprise systems independently.

Why It's Important?

The adoption of Senseye Predictive Maintenance by the automotive manufacturer highlights a significant shift towards leveraging advanced technology to enhance operational efficiency. This move is crucial for the automotive industry, which faces constant pressure to reduce costs and improve production efficiency. By predicting failures and reducing downtime, the manufacturer can maintain high production levels and meet market demands more effectively. This approach not only reduces maintenance costs but also extends the lifespan of machinery, providing a competitive edge in the global market. The success of this implementation could encourage other manufacturers to adopt similar technologies, potentially transforming maintenance operations across various industries.

What's Next?

As the automotive manufacturer continues to benefit from the predictive maintenance system, it is likely to explore further integration of advanced technologies to enhance other aspects of its operations. The success of this initiative may lead to increased investment in digital transformation projects, focusing on automation and data analytics. Other manufacturers may also follow suit, adopting predictive maintenance solutions to remain competitive. Additionally, the company may expand its use of predictive maintenance to other areas of its operations, further optimizing its production processes and reducing costs.

Beyond the Headlines

The implementation of predictive maintenance solutions raises important considerations regarding workforce skills and training. As technology becomes more integrated into manufacturing processes, there is a growing need for workers to develop new skills to manage and interpret data effectively. This shift may lead to changes in workforce dynamics, with a greater emphasis on technical expertise and continuous learning. Furthermore, the reliance on predictive maintenance technology underscores the importance of data security and privacy, as manufacturers must ensure that sensitive information is protected from potential cyber threats.