What's Happening?

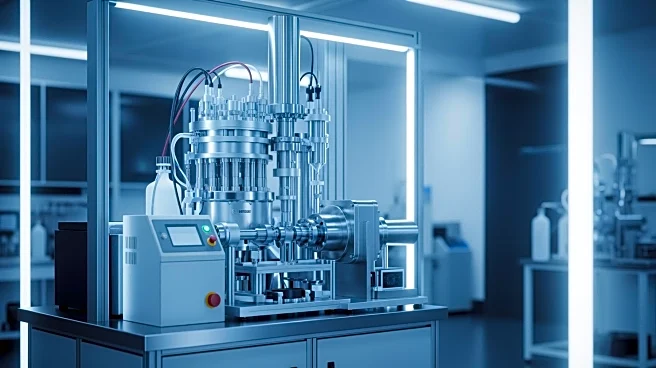

Micropore Technologies has introduced a groundbreaking membrane emulsification platform that transforms the manufacturing of long-acting injectable microspheres. These microspheres are crucial for sustained

drug delivery, releasing medication steadily over extended periods, which improves patient compliance and outcomes. The new platform addresses the challenges of scale-up and consistency in microsphere production by utilizing advanced crossflow membrane emulsification. This method allows for the commercial production of uniform emulsion particles in a reliable and energy-efficient manner. Key innovations include the development of straight-through pores, which eliminate blockages and reduce operating pressure, and the transition from a semi-batch to a continuous process. This advancement ensures precise control over droplet size, directly impacting drug release profiles and therapeutic outcomes.

Why It's Important?

The introduction of membrane emulsification by Micropore Technologies is significant for the pharmaceutical industry, particularly in the production of long-acting injectables. This technology offers economic advantages by removing the need for filtration steps, thus reducing manufacturing costs and simplifying processes. The ability to produce uniform microspheres with predictable drug release profiles enhances the development of sustained-release products, benefiting formulation scientists and pharmaceutical companies. The platform's aseptic design minimizes contamination risks, further improving product safety. As the demand for long-acting injectables grows, this innovation could lead to more efficient drug delivery systems, potentially expanding applications in veterinary medicine and beyond.

What's Next?

Micropore Technologies' membrane emulsification platform is poised to expand the applications of microsphere drug delivery. The company anticipates increased interest in long-acting injectables, driven by the platform's ability to improve economic viability and therapeutic outcomes. The continuous manufacturing process eliminates traditional scale-up challenges, allowing for seamless transition from lab-scale to commercial production. This could lead to broader adoption of microsphere technology in drug development, with potential new formulations and applications emerging in the future.

Beyond the Headlines

The membrane emulsification platform not only offers technical and economic benefits but also represents a shift towards more sustainable manufacturing practices. By reducing waste and energy consumption, the technology aligns with broader industry trends towards environmental responsibility. Additionally, the platform's ability to produce contamination-free products supports the growing emphasis on patient safety and regulatory compliance in pharmaceutical manufacturing.