What's Happening?

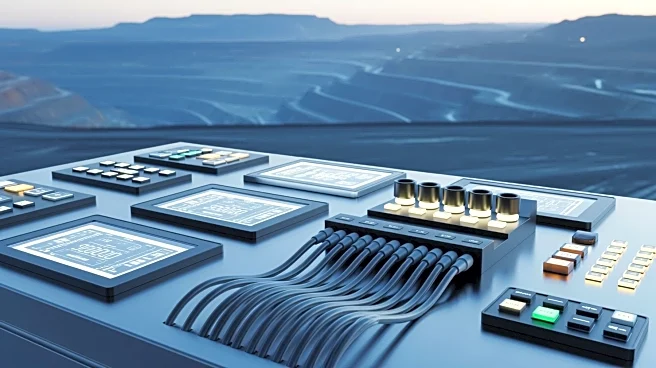

ABB has expanded its electrification and automation infrastructure at Boliden’s Aitik copper mine in Sweden. This upgrade is designed to enhance the mine's water storage, recycling, and monitoring capabilities, supporting the safe and efficient growth

of one of Europe’s largest tailings facilities. The project aligns with Boliden’s commitment to sustainable mining practices and long-term operational resilience. ABB's solutions include modular e-houses, switchgear, transformers, and a distributed control system for automated monitoring. These enhancements are crucial for managing the mine's operations amid increasing global demand for copper, projected to grow by 22% by 2035.

Why It's Important?

The expansion of electrification and automation at the Aitik mine is significant as it supports the growing demand for copper, a critical component in various industries, including electronics and renewable energy. By improving operational efficiency and sustainability, the project contributes to responsible mining practices. This development also highlights the role of advanced technology in enhancing resource management and environmental compliance. The success of this project could serve as a model for other mining operations seeking to balance productivity with environmental stewardship.

What's Next?

As the project progresses, Boliden will continue to focus on integrating these new systems to optimize their mining operations. The enhanced infrastructure is expected to provide real-time oversight and predictive maintenance capabilities, reducing downtime and improving efficiency. Boliden's commitment to sustainable practices may lead to further investments in renewable energy and advanced technologies. The mining industry will likely monitor the outcomes of this project to assess its impact on operational costs and environmental performance.